What is Punch and Die? Types and Applications Explained

The punch and die set is one of the most common tool sets used in sheet metal fabrication and manufacturing. The die punch combination makes sure that you get the right shape, cut, or bend in metal every time. The idea may seem easy, but to really understand how they work, you need to know about the numerous types, materials, and uses they have.

What is a punch and die?

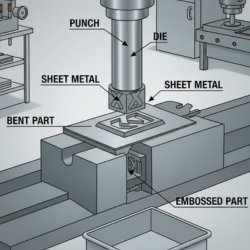

A punch and die is a set of tools used to cut and shape metal. The punch pushes on the material, and the die gives it a shape or hollow that the material can be sliced or crushed into.

The punch is a hard tool, usually composed of strong punch material, that hits or presses into the workpiece.

The die is the part that holds the sheet or block of material and forms or trims it when the punch touches it.

Different kinds of punch and die

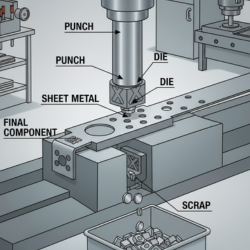

The design of the punch and die depends on how they will be used. Varied processes need varied forms, tolerances, and materials. Here are some of the most common ones:

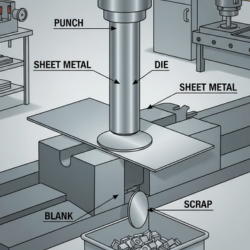

Blanking: This kind is used to cut a certain shape out of a sheet of metal. The blank is the cut-out portion that becomes the functional result.

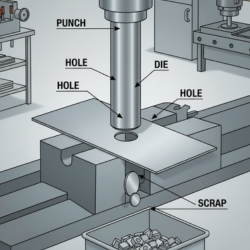

Piercing: In this case, the tool cuts holes in sheet metal, and the residual sheet is the main product. Piercing is a common method for making parts for cars and electronics.

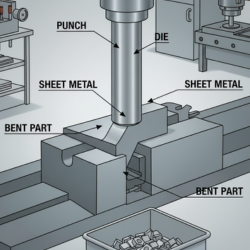

Bending: This design is used to bend sheet metal at exact angles instead of cutting it. Two popular ways are air bending and bottoming.

Making: This set is used in the deep drawing process to turn flat sheets into hollow objects like cans, cylinders, and car parts.

Embossing: This kind of press puts patterns, logos, or textures on sheet metal for ornamental or utilitarian reasons.

Strong punch materials like tool steel or carbide are used in each of these tools so that they can be used over and over again without wearing out.

Material for Punch and Die

In toolmaking, picking the right punch material is very important. Punch and Die Manufacturers use materials that can bear a lot of stress since the tools need to be able to handle wear, heat, and impact.

- Tool steels are the most frequent type because they are robust and last a long time.

- High-speed steels (HSS) are very hard and can handle heat well.

- Carbide is very resistant to wear and is employed in large-scale manufacture.

- Alloys: These are sometimes added to make things stronger and less fragile.

The correct die punch material makes sure that the tool lasts a long time, that the quality is always high, and that maintenance costs are low.

Design of Punches and Dies

For precision and efficiency, a good punch and die design is very important. When designing, designers think about things like the space between the punch and die, the thickness of the material, and the type of operation (cutting, bending, or shaping).

- Proper clearance keeps things from getting too worn out and makes sure the cuts are clean.

- To keep the tool from breaking, the design needs to find a compromise between strength and accuracy.

- Computer-aided design (CAD) is becoming a common tool for improving the shape of tools used in die making process.

With the appropriate design for the punch and die, producers may make less junk, work faster, and get the same results every time.

Uses for Punch and Die

Almost every type of production uses the punch and die technology. It is very useful in: because it can give accurate, reproducible findings.

- In the automotive business, making body panels, brackets, and holes for fasteners.

- Electronics: Making enclosures, connections, and other small parts.

- Aerospace: Making lightweight metal parts with great accuracy.

- Packaging: Making cans, lids, and other containers that are deep-drawn.

- Cutting and shaping sheet metal for everyday items is what household appliances do.

The die punch system is the most important part of making sheet metal, from small workshops to big factories that make a lot of it.

Last Thoughts

The punch and die set may look basic at first, but it is quite important in modern manufacturing. Industries may get consistent, high-quality results in a wide range of applications by carefully choosing the punch material and designing the punch and die.

The die punch system is still a reliable instrument for manufacturing dies, whether they are cutting, bending, piercing, or embossing. To choose the best solution for any fabrication demand, you need to know how it works and what kinds are accessible.