The words Industrial Engineering evoke an image of heavy duty machinery in our minds. Despite being heavy duty, this industrial equipment has to be extreme precise and reliable in addition to being robust. Eigen ensures that your machinery has precise and perfect metal stamped and fabricated parts for your industrial needs.

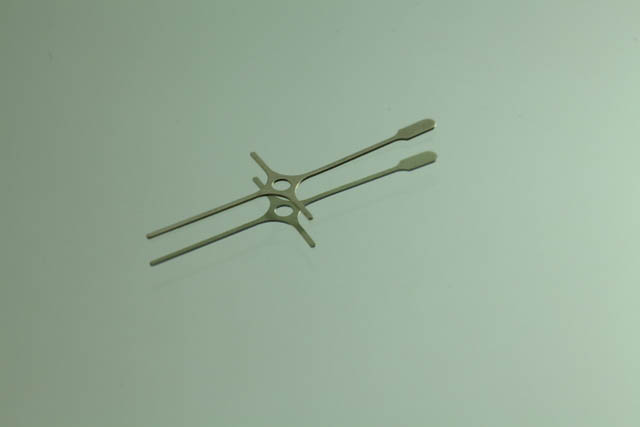

Precision Metal Stamping & Precision Sheet Metal Stamping for Industrial Engineering OEMs

Eigen provides precision metal stampings and fabricated parts for the Industrial Engineering industry’s biggest markets, including agriculture, construction, and power generation. We supply parts large and small – brackets, electrical housings, interior components – all of which are custom-manufactured to match our customers’ specifications. Our stamped metal parts and sheet metal fabrications consistently exceed customer expectations.

Our experienced engineers and technicians use the latest cutting-edge equipment to produce dimensionally perfect, tight-tolerance parts and components for industrial machinery. We pride ourselves on the consistency of our parts and our quick turnaround times.

We work with a range of materials and alloys, including titanium, cold rolled steel, and stainless steel; specialty materials can be sourced upon request. We maintain a large inventory of sheet metal, in various gauges, to meet your unique requirements.

Our Typical Application Areas are:

- Modular jacks

- Electronic Energy meters

- Industrial Batteries

- Impact matrix printers

- RFID Devices

To complement our metal stamping and metal fabrication capabilities and add greater value to our finished parts, we offer numerous secondary services. Our value-add services save you time and money by reducing or eliminating the need for additional processing on your end. We are a one-stop shop for fabricated and stamped metal parts.

- Finishing, painting

- Anodizing

- Assembly

- Machining

- Milling

- Drilling & tapping

- Deburring & cleaning

- Heat treating

- Welding

Advantages of Industrial Engineering in Component Manufacturing

Industrial engineering makes processes streamlined and efficient. A few advantages of component manufacturing are as follows:

- It improves the productivity of raw materials because it reduces waste.

- The manufacturing processes become safer, easier, and more rewarding.

- The better organization enhances the quality of the manufactured components.

- Industrial engineering reduces the overall cost of component manufacturing.

Applications of Industrial Engineering Services

A component manufacturer can apply Industrial Engineering Services in several ways.

- They can use the services to ensure the products never get stacked in the supply chain.

- Industrial Engineering Services can reduce the inventory by never making more than the demand.

- A component manufacturer can use these services to automate the manufacturing processes.

Why Eigen for Industrial Component Engineering?

Eigen will manufacture components according to the manufacturer’s specifications. These include precision metal stamping and fabricated parts, including

- brackets

- electrical housings

- modular jacks

- Electronic Energy meters

- Industrial Batteries

- Impact Matrix Printers

- RFID Devices

Eigen’s manufactured parts exceed customer expectations.

With Eigen manufactured components, you will get

- Quick turnaround times

- dimensional perfection

- Tight tolerance

- Various Value added services: finishing, painting, anodizing, assembly, machining, milling, drilling & tapping, deburring & cleaning, heat treating, and welding.

Frequently Asked Questions

There are several types of the component manufacturing process. Each one depends on the demand and availability of equipment.

- Job Shop manufacturing

- Repetitive manufacturing

- Discrete manufacturing

- Batch Process Manufacturing

- Continuous Process Manufacturing

- 3D printing

- Designing manufacturing products

- Quality control

- Producing technical documentation

- Ensuring that the products have labels and conformity markings

- Ensuring that the package contains manual and safety instructions