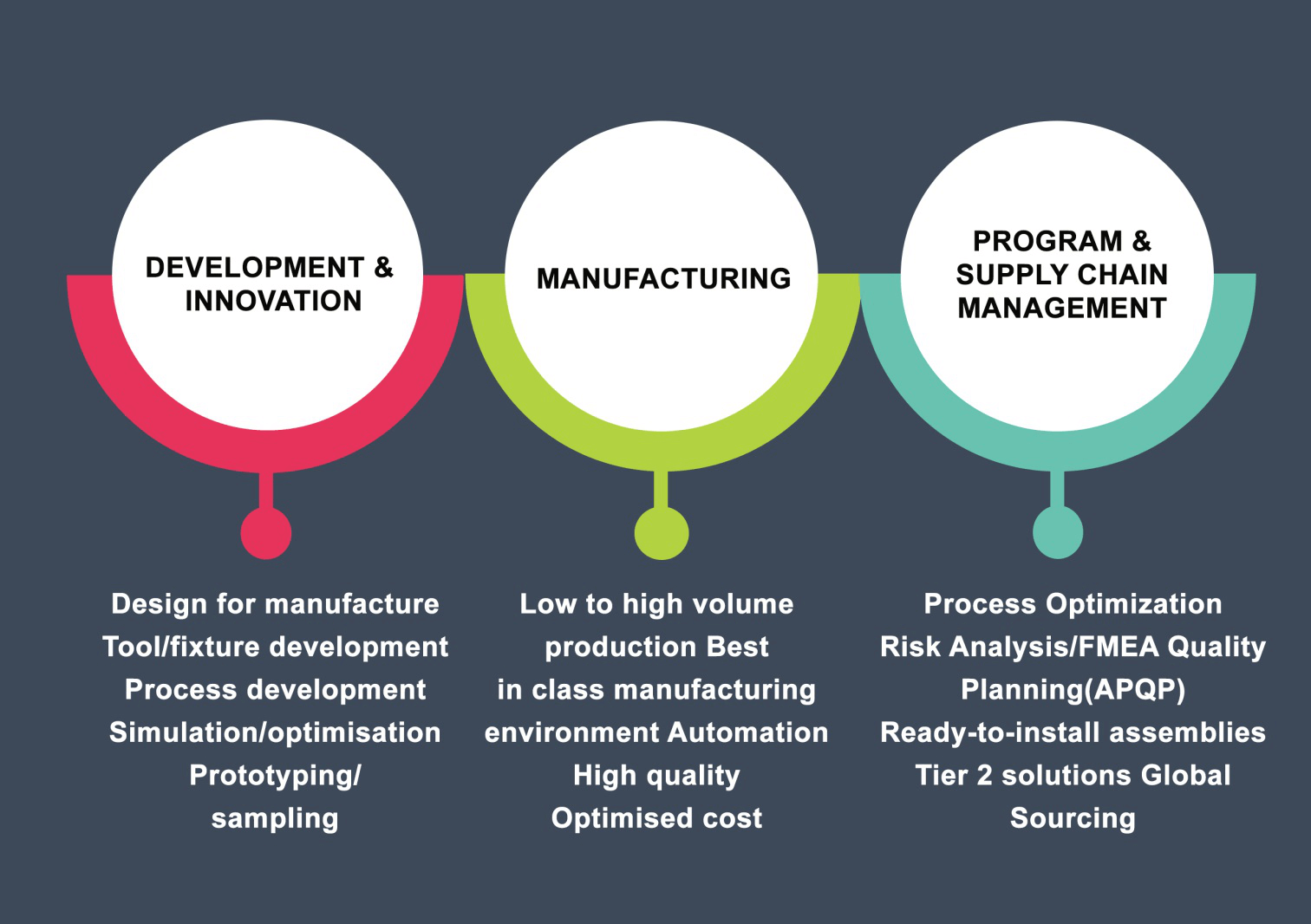

AS 9100 D, ISO 9001:2015 , ISO 45001:2018, ISO 14001:2015, ISO 9001, IATF 16949 Certified Company

Our Team

Mr.Yashovardhan Saboo

(CEO)

Mr.Yashovardhan Saboo Chief Executive Officer of the Company is a management graduate from IIM-A. He is an artist by heart but businessman by choice. Through a unique combination of creativity and entrepreneurship, the company under his leadership, has been delivering profits consistently. His passion for precision has inspired Eigen to pioneer in complex yet precise parts like relays and connectors for Aerospace industry, Sensors for auto electrical etc..

Mr. Sanjeev Masown

(Executive Director & Group CFO )

Mr. Masown is Executive Director on the Board of KDDL Limited and is responsible for EIGEN Engineering business growth through strategic direction and leadership initiatives.

Mr. V. Srinivasan

(Business Head )

Mr. Srinivasan is a graduate in Mechanical Engineering from Anna University and has undergone Executive Education Program at IIM-B and is a Six Sigma Black Belt.

Has 30 years of experience in the Automotive Industry proficiently managing Product Development, Tooling, Manufacturing Operations and Business Management. He was heading precision Fine Blanked parts business for Tube Investments of India and contributed for its significant growth.

As a Business Head of Eigen engineering, he will be providing strategic direction as well drive the execution of growth strategy for the company.

Mr. Jagadeesh B Patil

(Chief Marketing Officer)

Mr. Jagadeesh B Patil, leads the Sales, Marketing & Business Development matters for EIGEN and oversee the execution of Business Growth Strategy for the Division focusing on developing and managing multiple capabilities for expanding Customer base in both domestic & overseas markets. He is BE, MBA graduate with vast experience of more than 20 years in Sales & Marketing function.

Whats new at Eigen

News | 13-09-2019

Certificate for The Best Quality and Delivery Supplier for The Year 2018-19

A Multinational Clientele

With operations around the world, chances are Eigen has a presence where you are. Find out what we do in your country, who our partners are and how we're working to develop an even stronger, more satisfied clientele across the globe.