Benefits of Custom Metal Stamping

- Metal Stamping |

- Oct 3, 2022

Metal stamping is a manufacturing process used to make components in various industries. These sectors include medical, aerospace, automotive, and many others. As global markets evolve, there is a need to produce large quantities of complex parts to satisfy these industries. Therefore, the availability of custom metal stamping comes with a lot of benefits, and they include:

What’s Metal Stamping?

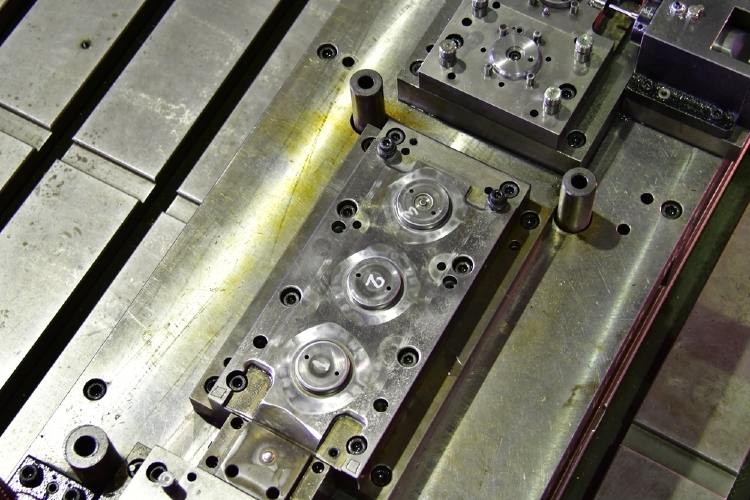

It’s a manufacturing process that transforms flat metal sheets into specific shapes using a progressive stamping machine. It has various metal forming methods, including bending, punching, blanking, piercing, extrusion, and many others. So, what are the benefits of custom metal stamping?

Contact Us To Know More About Our Custom Metal Stamping Services

Benefits of custom metal stamping

Custom metal stamping has a lot of benefits for people in various industries. The main benefits of customizing include accuracy, compatibility, durability, customization, ownership, and reliability.

- Reliability

Customizing parts makes it easy to work with the design and engineering team throughout the process. Due to this, your products can meet the cost and manufacturing requirements per the plan. In addition, it ensures that you can depend on the part’s performance during use as they meet your preferred standards.

- Accuracy

The reliability of parts comes from the assurance of their accuracy during production. The right customization to meet your needs includes adhering to your set tolerances. The application doesn’t matter; you need well-formed parts to work perfectly. If your parts are well created, they will perform the task as expected. To get accurate parts as per your expectation, you can use custom metal dies to make it possible.

- Offers compatibility with your components

Most components might not align with the rest of your products. To achieve compatibility, ensure you customize the parts. When you do this, you ensure the parts meet the shape and size your project requires. Through a progressive stamping machine, you can pick different metals and customization options to make the parts. The Machine will ensure the parts are well fabricated and compatible with the components they need to work with.

- High durability

Parts’ durability is essential in many sectors. For instance, in the automotive sector, the components need to fit together and work in harsh environments. Customization using a custom metal die or other materials ensures you make durable parts to fit the function. The ability to pick materials to make the parts stand the harsh conditions makes customization better than standard parts.

- Allows complete part customization

When you use standard parts, you only have a choice to add holes or choose the finish. However, you have more options when you customize parts for metal stamping. You can tailor the part per your preference and take part throughout the creation process. Also, the company helping in creation assists you in design, material selection and identification of finishes, and more. The good thing is you get to be part of the whole process giving your opinion on everything.

- You get proprietary ownership.

For standard parts, the manufacturers own the proprietary rights; however, with the customization, you gain the proprietary ownership. Note that when a standard die is used to make the parts, the experts only use it for the metal stamping for your part. Customization gives you rights to parts and designs, keeping competitors from recreating your products using the same metal-stamped parts. Therefore, if competitors need to make parts, they have to customize their dies to make the parts. So, by customizing your parts, no one can use your dies because you own the rights and design.

As mentioned earlier, customized parts are used in various industries, which include:

- Oil and gas sector

In this industry, there’s a need for small seals, connectors, and large components such as pipeline parts. The parts work in extreme temperatures, prone to salt exposure and high moisture levels. It means the parts need to have a high level of durability and reliability to withstand harsh conditions.

To achieve this, you need to pick metals that can withstand frequent use and heavy wear. All you need to do is to optimize part production through customization. When making large orders of small seals for refineries, pumps, or transport, progressive stamping can do it. Using a progressive stamping machine, you can produce parts at a low cost and in large quantities.

- Medical Industry

In the medical industry, ventilators and other medical devices require customized parts. However, some regulations control materials used and tolerances when making these parts. Medical components must be created from metal resistance to wear or react when used inside or around the human body. For example, implanted device enclosures are made of titanium to protect the devices from the body. Other devices in this industry that use this kind of enclosure include ear, heart, and brain implants.

Customization of medical components is essential because the patients’ sizes and shapes differ. Doing this helps to ensure the devices are compatible with the patients. Other components are made using custom metal stamping using medical-grade metal surgical tools.

Custom metal stamping is applied in various sectors. They include the oil and gas, medical, construction, automotive, aerospace, and electronic sectors. People prefer it because the parts created offer several benefits more than standard parts. When using this method, you get durable, reliable, accurate, and compatible parts for your specific application.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.