Important Steps to Ensure Metal Stamping Success

- Precision Metal Stamping |

- Sep 20, 2017

Metal stamping is a crucial process, and there is a lot of thought, planning, and actions that happen before stamping a component. When a metal part is designed in the most cost efficient manner, it will help metal stamping suppliers to reduce product cost, enhance product life, and also cut down on the production time. Metal stamping companies have a wide array of requirements, from stamping parts in automotive to stamping micro-mini parts made from extremely thin material. There is also a requirement to make parts with high strength steel alloys for increased strength and durability. Most of the customers need crucial metal stampings to deliver high performance and tight tolerance. In simple words, no two metal project stampings are alike, but each project can be based on the same principle. The below-mentioned steps are important for metal stamping companies to make sure that the parts are designed and manufactured to exact specifications.

Get the metal stamping design from the start

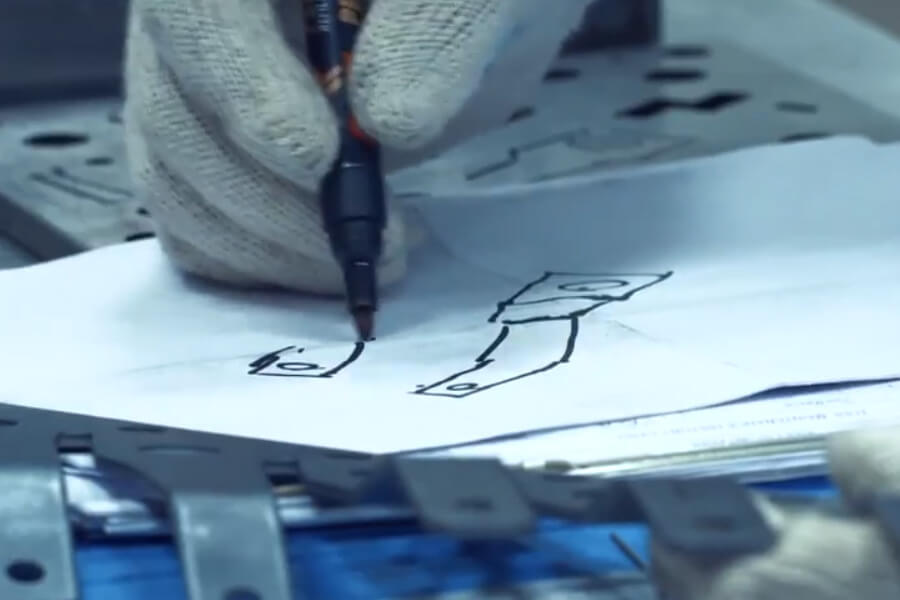

If the engineers at precision metal stamping companies are asked about how to make the process run smoothly, they will want the stamping companies to involve them in the designing process from the beginning. In some cases, the CAD drawings are not realistic and the limitations of metal stampings are not being taken into account. The metal stampings that perform best are based on the collaborative process and product design. This process allows the precision metal stamping company to consider the specific requirements of clients by considering optimal metal stamping design and production, and this includes assessment of materials as well.

When the engineers are involved in designing from the beginning of the process, they can propose improvements in the designs that in effect can save significant time and money for the company. For example, the engineers may recommend ways in which the packaging of parts can be changed, and also the complex changes such as eliminating unnecessary steps by reconfiguring a part. This allows saving on the overall manufacturing cost and bringing down expenses. The collaborative efforts of designers and engineers will help the company to not only save on cost but also come up with efficient steps to come up with the final product.

Have a proper projection of requirements

Open communication is the key to success in precision metal stamping as well. As a metal stamping supplier, it is best to be open about the anticipated requirement of the part and the final assembly of a product. This includes discussing the project volume and the release frequency over the year. Once the engineers have a complete idea of the scope of the manufacturing process from the assembling to the final assembly of parts, they can recommend certain changes or redesign metal stamping process to reduce the overall cost of the process.

For example, a simple thing as stacking the metal stamping at the press in an efficient way can prevent secondary handling and reduce the overall cost. The projection of metal stamping will have a strong bearing on how the stamping is produced. It is the high volume products that require robust tooling in most cases and not the low volume products, and this is where proper forecasting will help in executing the process. The engineers working on different areas of metal stamping need to work together in order to understand the critical areas of a part being stamped and the efficient ways to run the process.

Critical tolerance of metal stamping need to be evaluated

Some suppliers specify the tightest tolerance because they feel that it tightest tolerance is always better and has a reduced risk of part failure. However, the tighter tolerance also increases the price to produce a part because then the supplier has to spend more time to develop the die and to maintain the specifications. The engineers work hard to understand the critical tolerance of metal stamping, and then recommend ways to efficiently carry out the stamping process. This, they are able to come up with the right techniques and processes to save on the overall manufacturing cost.

Eigen offers you efficient results

If a metal stamping company is able to follow the above-mentioned steps, then the company can provide amazing results to their clients. At Eigen, our teams work together, the engineers put on their thinking caps, the design is improved, and as a result, the end result is of really great quality. We ensure that communication is transparent within our teams, and as a result, our engineers are always involved from the inception to implementation of a particular project. No two metal stamping projects are alike, and so every project needs to be given equal importance to get efficient results. The joint effort does not only save on the overall costs and efforts for the company, but we are also able to provide only the finest results to our customers.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.