How Metal Stamping Tools Adds Value to Manufacturing?

- Precision Metal Stamping |

- Sep 23, 2019

Metal Stamping industry is one of the leading industries across the globe. The reason for the high demand of Metal stamping in the global market is due to the rise in technology, urbanization and industrialization. Another reason for the rise in Metal stamping is because it is versatile and it can be used in manufacturing products for various industries starting from agriculture, aerospace, automobiles, medical, electrical, electronics and so forth. Now that we have understood the importance of metal stamping, we will discuss in detail about – What is metal stamping? What are metal stamping tool and progressive tooling? How did these metal stamping tools add value to manufacturing?

Metal Stamping:

Metal stamping is a process in which a flat metal sheet is used in a stamping press in order to convert the sheet into various designs and shapes.

During this process, different techniques like punching, piercing, bending and so on are used along with a lot of tools and dies to achieve the desired shape or design of the metal sheet. This takes us to the next question as to what are metal stamping tools?

Metal Stamping Tools:

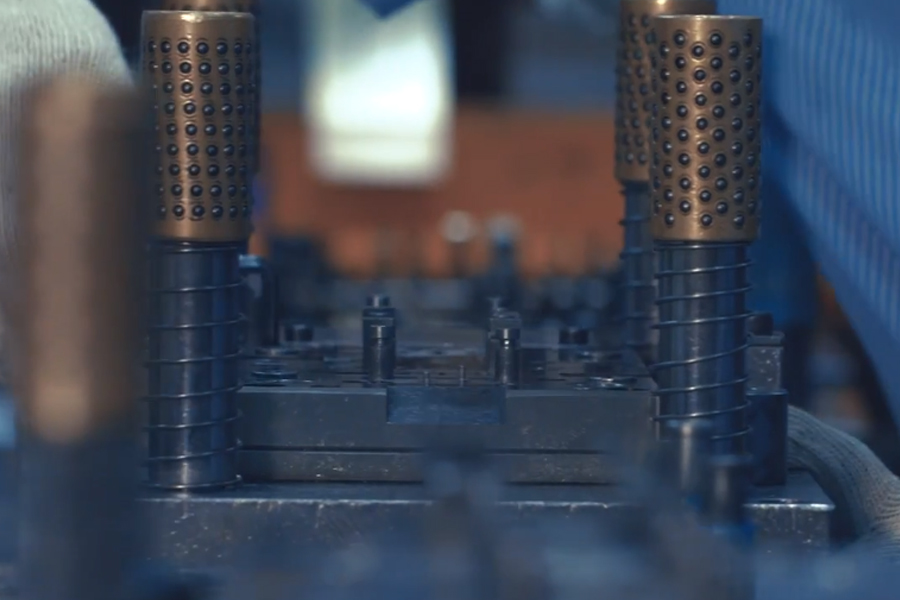

Metal stamping tools play a major role in the shaping and designing of flat metal sheets. These tools are made by professionals who use the latest technology or software available in the market to manufacture specific metal stamping tool. Each stamping tool has a metal space or a cavity which when punched on the metal sheet gives the required shape or design. One of the techniques used in metal stamping is progressive tooling. Let us first examine what is progressive tooling?

Progressive tooling:

As the name suggests progressive tooling is developing a finished product gradually and in several steps on different stations. It begins with inserting a flat metal sheet at the beginning of the spool and then slowly it continues to move from one station to another station by punching, piercing and bending to reach the final product.

This gives us a clear picture about progressive stamping tool and the stamping tools, we will now have a closer look at how Metal stamping tools add value to manufacturing. Following are the many ways in which metal stamping is advantageous:

High-speed production:

Metal stamping is a process which helps in manufacturing a product at high speed. This means that metal stamping tools help to generate a number of finished parts within a short period of time and thus it helps to save time.

Low pricing:

This is also another reason which makes it affordable for any industry to invest in metal stamping so that they can manufacture their own products.

Less wastage:

Metal stamping is cost-effective because it uses major parts of the metal sheets in manufacturing a product. Hence, there is a very low wastage rate and it helps in lowering the overall cost of the finished product.

High Quality and Accurate:

The amazing thing about metal stamping is that it can manufacture huge bulk products that are identical and accurate even at a high speed. This clearly means that there are fewer parts that get deformed or are damaged and it maintains very high quality.

Precise:

Metal stamping tools are unbelievably great when it comes to precision and it’s complex design. It is so precise that even the most complicated and toughest shapes are designed skillfully and smoothly. Hence, metal stamping tool is reliable for manufacturing any desired product.

Less downtime:

This is another advantage of using metal stamping tools as the continuous process of manufacturing the finished product enables it to fewer tooling changes and allows in longer production run.

To conclude, today’s technology is way ahead and rapid increase in the knowledge of technical skill, especially in the field of metal stamping. Hence, there is no other better substitute for metal stamping when it comes to manufacturing a simple shape or the most intricate designed product. Be it efficiency or accuracy metal stamping tools indeed adds a lot more value to any kind of manufacturing.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.