Revolutionizing Automotive Design: The Impact of Advanced Metal Stamping Techniques

- Design and Engineering |

- Feb 6, 2024

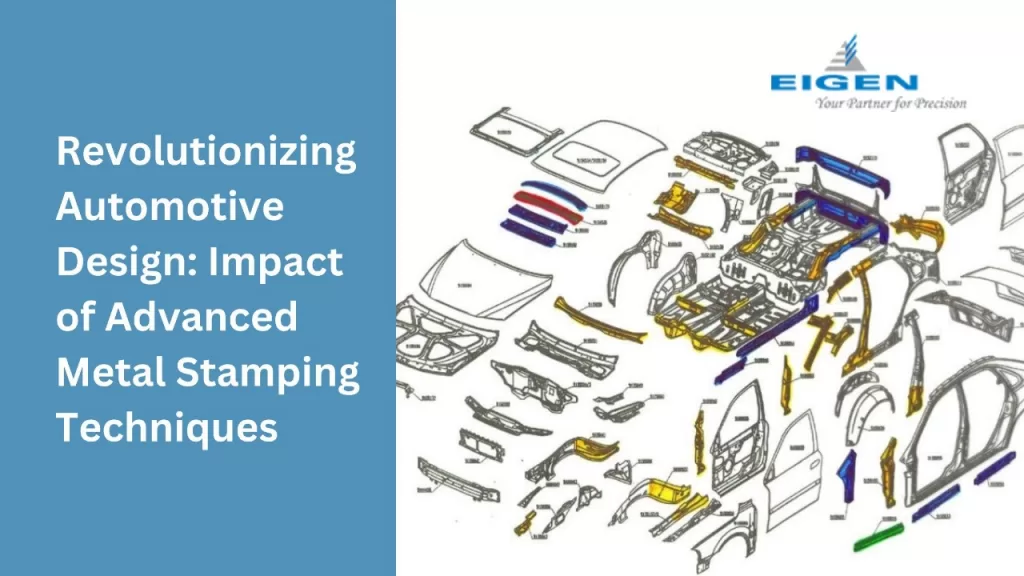

Precision and accuracy play an important function in metal stamping. With advanced metal stamping, the standard for efficiency, innovation, and cutting-edge technology has risen tremendously in the industry.

The automotive stamping suppliers provide cutting-edge solutions that allow metal stamping objects of the very best quality to be made with extraordinary accuracy. The efficiency of the advanced metal stamping technique has distinguished metal stamping from other techniques. Read below to learn about the impact of advanced metal stamping techniques that have revolutionized automotive design:

1.High Accuracy

The capacity to get micron-level precision is probably the largest advantage of advanced automotive stamping. Automotive component manufacturers can mold metals into the most intricate form with the help of advanced metal stamping with the intricacy and delicacy of this approach. As sensors and camera systems are used to verify the size at some stage in the process, there is almost little hazard of errors.

The material is positioned right into a stamping press, which uses a unique die to create metal forms. Other strategies, such as stretching, bending, curling, embossing, and many others, are used to get the final result. With an emphasis on high accuracy, the advanced metal stamping technique has become the best process in high-end manufacturing.

2.Uniformity and high volume of production

Multiple runs of loads to hundreds of thousands of parts can be produced through advanced precision metal stamping. This is a better rate of production than welding, fabrication, CNC machining, or any other different metalworking strategies. When manufacturing massive amounts of metal components, advanced metal stamping is good for huge-volume manufacturing.

With minimum to no extra setup or modification required in between production runs, advanced metal stamping is a flexible process. In comparison to other commercial mauprocesses, precision metal stamping reveals an extra homogeneity.

After production, assembly and quality assessments are made less difficult because all items are stamped from sheet stock. It gives them uniform wall thicknesses and similar surface finish.

3.Cost efficiency

The low-cost nature of the advanced metal stamping process has revolutionized automotive design. It makes it possible to hurry up manufacturing while substantially reducing processing time. Companies can cut labor costs, the number of employees, and their reliance on equipment through a growing production pace.

Advanced metal stamping helps businesses by enhancing the efficiency of production instances. Efficiency like this is thought to be a satisfactory alternative for decreasing costs. It is recommended that businesses get support from metal stamping companies that make use of automatic metal stamping when there is a need for bulk components. The automotive, semiconductor, electronics, and medical industries can gain from this approach.

4.Ease of use

As recent advancements in metallic stamping create complex designs with little device changes, engineers and designers find it easy to use them. Early on in the product development process, concept research can be facilitated through this selection, which gives more layout flexibility.

There will be fewer die changes for every iteration of the part design, which also helps cut expenses by doing away with waste. As they require much less machining time in subsequent operations, the designed additives are less difficult to fabricate with the use of precision steel stamping. Workflows end up more powerful as a result, mainly in huge production volume environments.

5.Reduces material waste and fallback choices

As the advanced metal stamping technique employs the least amount of material necessary to create the pieces, precision metal stamping is a cost-effective manufacturing technique. The absence of problematic secondary processes, such as CNC machining, which can be costly and time-consuming, allows producers to get their desired products at lower cost.

After manufacturing, secondary methods like thread slicing are normally not required with advancements in metal stamping. Pre-drilling holes, counter-sinking, and reducing threads are a few examples of the way the process produces precisely formed functions without error. The hand finishing is negligible after stamping, which once more saves time and money as secondary activities from time to time increase charges and put them off to market.

6.Amazing adaptability

Undoubtedly, metal stamping could be very popular in many industries because of its flexibility. It makes it possible to form the lightweight yet robust metal into complicated shapes and small sizes. However, during the procedure, specifications can be followed without any issues.

For specific industries, there are many alternatives to metal stamping. So, check if the metal fabrication company offers engineering, design, packaging, and assembly services that are specific to your industry and company.

Final thoughts

The advanced metal stamping process has revolutionized manufacturing in automotive metal stamping companies with its automotive design. Wishes of manufacturers, including budget, machine capacity, and tool quality, are taken care of by the latest developments in metal stamping. Now, advanced metal stamping has become well-known for its remarkable accuracy and dependability, which makes it the material of choice for a wide range of applications.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.