What is an Electrical Busbar? Types, Materials, and Applications

- Electrical & Electronics |

- Nov 19, 2025

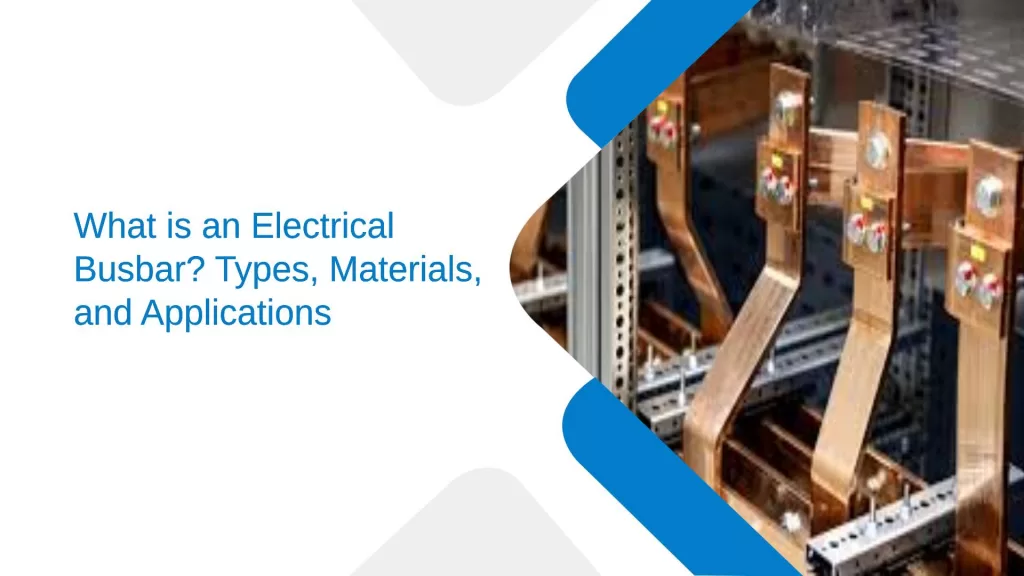

Have you ever wondered what carries the huge amount of power inside a panel or substation? It’s not a cable, but it is a solid metal bar called a bus bar in electrical systems. This hidden part works like a main highway for electricity, keeping power moving fast, safe and steady. Without busbars, modern buildings, factories and power stations would struggle to run even for a minute.

What is a Busbar?

A busbar is a flat or round metal bar made of copper, aluminium, or brass. These bars are capable of carrying high power and thereby interconnecting various parts of the system without requiring the use of thick cables.

The standard electrical bus bar is located within a busbar panel, where it serves as a connection between switches, circuit breakers, fuses and metres. The current in the busbars is less resistant due to the large surface area, and thus the heat is minimised and the system safety is enhanced.

Busbars are also made through precision metal forming processes like copper stamping and aluminium stamping, which give smooth edges and exact sizes.

Function of a Busbar

The main function of a bus bar system is to share electrical power from one main supply to several circuits. This makes them useful in homes, buildings, factories and large power networks.

bus bar in a power system offers these key benefits:

- Low power loss

- Clean layout without too many cables

- Easy expansion when new circuits are added

- Safe and even distribution of electricity

Such properties make busbars the crucial components of switchgear, panels and other electrical distribution systems.

Types of Busbar

Busbars come in different shapes and systems depending on how they will be used. Below are common types of busbar designs.

By Shape

Flat Busbar: It is the most common type, and it has a wide surface area for better heat control.

Rectangular Busbar: It is used for high-current systems as it is simple to count and connect.

Round or Tubular Busbar: It is used in places where flexibility or cooling is important.

Flexible Busbar: It is made from thin copper layers and is used for movement or vibration-heavy areas.

By Application

Single Busbar System: It is simple and cost-friendly, and it is used in small panels.

Double Busbar System: Added flexibility and backup options, so it is good for larger buildings.

Ring Busbar System: Used in substations for high reliability and lower outage risk.

Main and Transfer Busbar System: Common in power plants where loads need switching without downtime.

All these types of busbars help control and move power in a safe and planned way.

Materials Used in Busbars

Busbars must carry large amounts of current, so the material matters. The most common ones are:

Copper Busbar

- Very high conductivity

- Strong corrosion resistance

- Used in critical systems like switchgear and substations

Aluminum Busbar

- Light in weight

- More cost-friendly

- Used in general distribution and large trunking systems

Brass Busbar

- Used for special mechanical or decorative needs

- Lower conductivity but strong and durable

Some busbars are coated with tin or silver for extra protection and longer life. These coatings prevent oxidation and help maintain clean contact points.

Advanced plants use copper busbar manufacturing or aluminium busbar fabrication systems to shape and finish these bars for real-world use.

Busbar Insulation and Safety

A busbar insulator keeps the busbar from contacting other parts and causing short circuits. Insulation is vital in high-power systems where a small fault can cause major damage.

Modern systems use different types of insulation:

- PVC coating

- Epoxy insulation

- Air-insulated chambers

- Insulated busbar systems in switchboards

These layers keep the electrical bus bar safe to handle and maintain.

Applications of Busbars

Busbars are used anywhere electrical power needs to be shared across many circuits. Some major uses include:

- Industrial Plants: Running machines, motors and heavy equipment.

- Commercial Buildings: Busbar panel helps manage lighting, lifts, HVAC and backup systems.

- Power Stations & Substations: Used for switching loads and transmitting high current.

- Renewable Energy: Used in solar inverters, battery banks and energy storage units.

Because busbars are compact and strong, they support both simple electrical distribution and advanced busbar system designs.

Advantages of Using Busbars

Busbars come with many strong benefits that make them better than cable networks:

- Compact design: They save space inside panels and keep layouts neat.

- High current strength: Their wide surface area helps carry large currents without overheating.

- Easy maintenance: Open and clear connections make checks and repairs simple.

- Stable and safe power flow: They reduce hot spots and keep distribution steady.

- Flexible for expansion: New loads or circuits can be added with minimal changes.

These advantages are why power busbar systems are preferred in modern electrical setups over traditional cable-based layouts.

Read More: High Speed Stamped Metal Stamping Parts and their Benefits

Conclusion

Busbars are the powerful and dependable elements that ensure the safety and proper order of the electrical systems. If a busbar system is built using the right material, shape and design, then it will not only enhance performance but will also minimise the production of heat and facilitate the distribution of power in an even manner.

If you are looking for top-notch copper or aluminium busbar parts with accurate stamping and fabrication, then Eigen Engineering is at your service. Our advanced tools and skilled team deliver accurate, durable, and custom-made busbar components for all applications. Visit our site to explore our full range of metal stamping and busbar solutions.