Learn How Manufacturing is Driven by Precision Tool and Die Industry

- Progressive Tooling |

- Dec 17, 2018

Any kind of manufacturing is driven by market demand, precision tool and die making is no different. To appreciate tool and die manufacturing better, it is important to retrace the evolution of the manufacturing industry.

In the very beginning, products were made by hand. While there was a value for quality, due to the nature of production, only limited quantities could be manufactured. After the arrival of Industrial revolution, machines were introduced and products could be manufactured faster. More people could be employed to operate machines. Then came the assembly line, where individual components moved through a line that involved additional work and components added to create a complete finished product. Lean manufacturing followed, here the focus was to improve efficiency and reduce wastage. The use of robots further improved manufacturing with specifications fed and machines doing the production and assembly. Workforce was to just monitor so that there are no breakdowns and ensure that targets were met.

The introduction of power press paved way for press dies. This was further improved using NC and CNC machines. This enabled precision manufacturing in a repetitive manner using computer technology driving the machines. Which leads us to precision tool and die making.

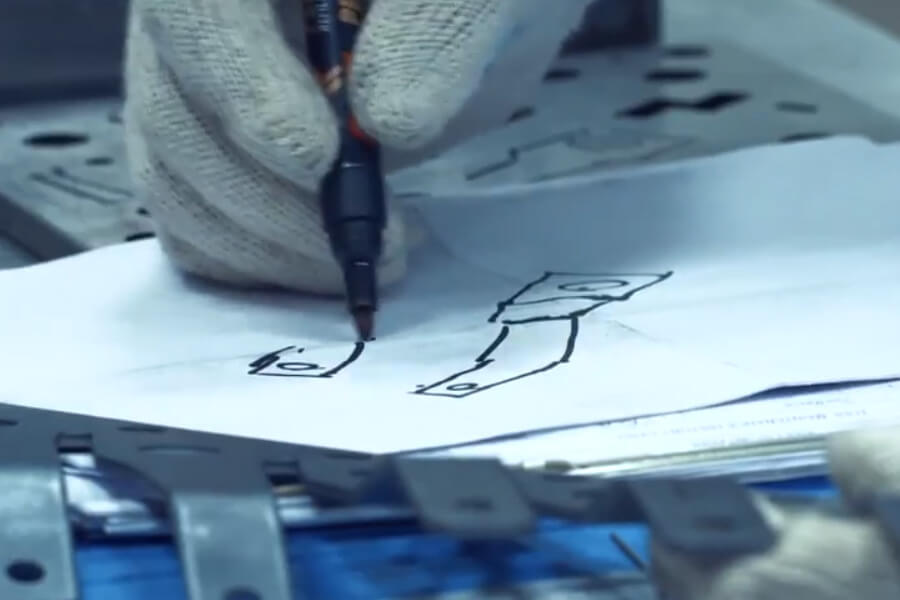

Today’s manufacturing demands accurate production at high speeds. A tool and die maker is approached when manufacturers want to create custom components based on different volumes in a particular time period. This is made possible using precision tool and dies. The basic functions of a tool are to cut or shape metals and other materials. The die is used for stamping, molding and forging materials like metals, plastic etc. A proper tool and die design will aim to maximize the capabilities of tool and die manufacturing.

It is obvious manufacturing has become sophisticated. This calls for cutting-edge technology and skilled manpower to meet industry demands. Precision Press Dies is now at the forefront of modern manufacturing for the following reasons.

Speed:

Progressive tooling helps produce mass volumes of components at a very fast rate

Accuracy:

The tool and die are designed with detailed specifications to accurately reproduce the concept design

Cost:

This type of manufacturing results in lower cost per unit due to efficiency of speed, volume, base material usage.

Lean Production:

The entire unit is designed to reduce wastage thereby promoting more efficient use of raw material.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

Customization:

The set-up can be customized to create complex shapes using a single tool and die configuration.

To achieve all of this a holistic tool and die design approach is needed.

The entire process is highly automated with very little manual intervention so as to generate results. This means that careful planning is required for fabricating the entire set-up. A successful tool and die maker have clear understanding of client requirements, have adequate design and manufacturing expertise to create the desired combination.

At Eigen, we offer robust precision tool, precision die and stamping and die manufacturing services. We have a meticulous 4 step approach that enables us to exceed expectations. Here is a snippet of what these processes consist of.

Client Requirements:

We clearly establish client requirements and document to create the prototype.

Die Shape:

Based on inputs, we design and manufacture the desired shape that will yield the desired outputs.

Sample Test:

There are different tests performed to verify whether quality and other manufacturing needs are met by the tool die combination.

Final Production:

The product after completion of tests is sent to final production. QC ensures that the final product produced has no deficiencies and meets all the client’s needs once used in manufacturing.

All of the above is made possible due to harmonious working relationship of our various teams. We are proud to state that we have the perfect blend of machinery and manpower to deliver results.

It is important to go by the reputation of tool and die manufacturing companies to align with a proper production partner. We have over 12 years of experience and built a solid reputation as a reliable tool and die manufacturing company.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.