A Quick Look at How the Sheet Metal Punching Process Works

- Design and Engineering |

- May 2, 2019

Sheet metal punching is one of the key techniques with which you can create a variety of customized shapes out of sheet metal of varying thicknesses.

But the question is how does the sheet metal punching process work? Take a brief look at the process:

Sheet metal punching process

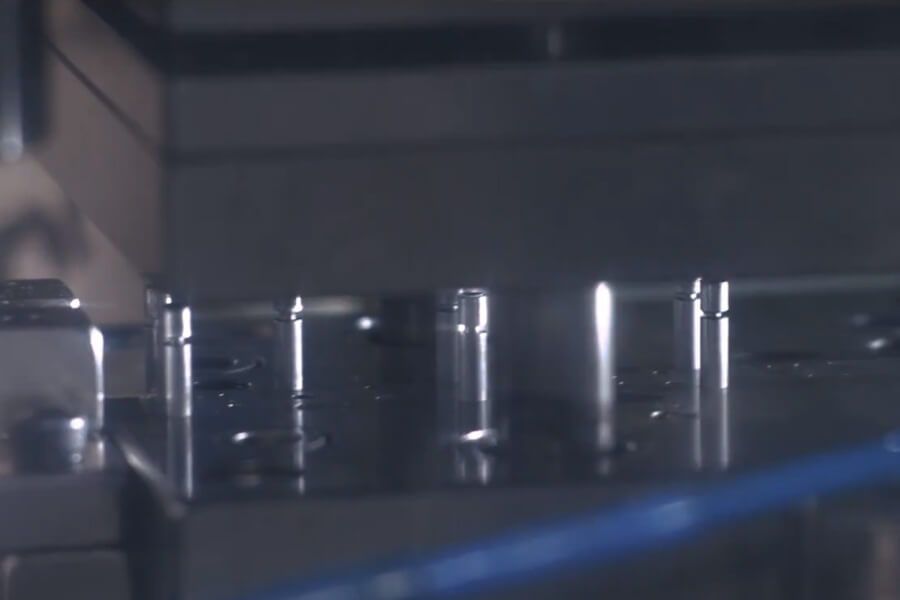

The sheet metal punching machines use metal punches and die. Punches pass through the sheet metal, while the dies are located on the opposite side of the metal piece. These dies support the metal and ensure that the metal does not break, further, they also help punches in making accurate holes. This process allows punch and die manufactures to form sheet metal parts of any shape and design, depending on the needs.

To create holes and indents in a piece of metal modern sheet metal punching is carried out by using state of the art equipments.

But the principles remain the same such as:

The sheet metal being punched is sandwiched between the metal punches and dies. The punch moves downward into the die. This process causes the sheet metal beneath the punch to be sheared from the surrounding material. Such sheared metal is collected into a container for later use or for recycling. Repeating these steps is used by the punch and die manufacturers until the desired shape is achieved.

One particular process that is used often to achieve customized hole shapes is known as “nibbling.” In this process, an extended series of very small holes are punched one at a time. These holes can create customized contours to fit particular needs.

EXPLORE OUR DESIGN & ENGINEERING SERVICES

Do different holes and shapes need different metal punch and dies?

Not really. If you don’t want to invest in a specific tool/die and the quantity is minimal, then you can combine the dies you’ve already have to attain the desired shape. If creating specific shapes becomes more assiduous, you could buy a specific mold.

Also Read: Best Die Punch Manufacturing Services and Capabilities

Can all metals be punched?

Thanks to the advancement of sheet metal punching and know-how, almost all metals can be punched such as stainless steel, iron, brass, aluminum, copper and special alloys. This flexibility allows the use of sheet metal punching in a wide range of industries such as aerospace, industrial engineering, automotive, electronics, manufacturing, textiles, as well as many other industries.

Aspects which affect punch quality?

The quality of each punch is determined by a few important factors, like the size and shape of the metal punch and die, the amount of force applied, the condition of the metal punch and die, the thickness of the metal being punched and the type of metal being punched. For instance, when punching a circular hole, it is recommended that the minimum diameter of the hole should remain larger than the thickness of the metal. However, for sturdy metal alloys, the size of the hole would not matter that much.

It is a good idea to follow certain rules in order to get better performance from the punches and matrices during punching. For example, for round holes, the minimum diameter should be greater than or equal to the thickness of the sheet. For shaped holes, the shortest side should be equal or greater than the thickness of the sheet.

Also Read: What Do Sheet Metal Punch Dies Do In the Manufacturing Industry

How long can you use your metal punches and dies?

As a general rule, your sheet metal punching tools have a medium tool life of 400,000 to 600,000 strokes. However, there are a set of very useful suggestions that help punch and die manufacturers to ensure that their tooling has a longer life. For example, by removing dirt with compressed air, clean rags, further you can be diligent in lubrication and cleaning. Regularly check the cutting edge of the metal punches and dies, and when necessary proceed with sharpening. Furthermore, in the sheet metal punching process, it is vital to process punching on the right materials and use the right energy power.

DISCUSS YOUR METAL DESIGNS NEEDS? CONTACT US!

Can punching shape the sheet metal?

There’s a different process for shaping sheet metal that is at times carried out by the same equipment called sheet metal stamping. The sheet metal punching process aims to punch a hole through sheet metal whereas, stamping aims to form the metal to create specific shapes. Since laser does not use physical force, it cannot shape metal reliably in the same way that a CNC punch or press can.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.