All about Metal Stamping Dies and Their Essential Functions

- Precision Metal Stamping |

- Mar 20, 2018

We are living in a world that always has something new to offer. Gone are the days when we had to wait for something new to be introduced. If we skip a day looking at news, we skip a new innovation. Well, the several industries make up innovation in our times and ensure that the customers are always provided with the best solutions. Precision metal stamping companies keep the several innovative industries happy with the constant supply of stamping components designed with client expectations. In the core of this entire chain is the precision metal stamping dies.

The exceptional role of metal stamping dies

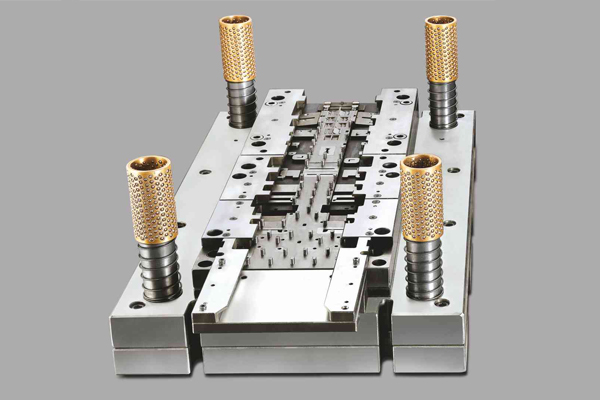

When it comes to cutting and shaping a particular metal in the provided shape, it is the stamping dies that play a crucial role. The dies are carefully designed and then customized according to the specific items that are going to be stamped. The dies are crucial in stamping small items to the really advanced tools and components being used in several industries. So in order to get the most efficient results in the manufacturing processes, the industries make best use of metal stamping dies.

The working of metal stamping dies

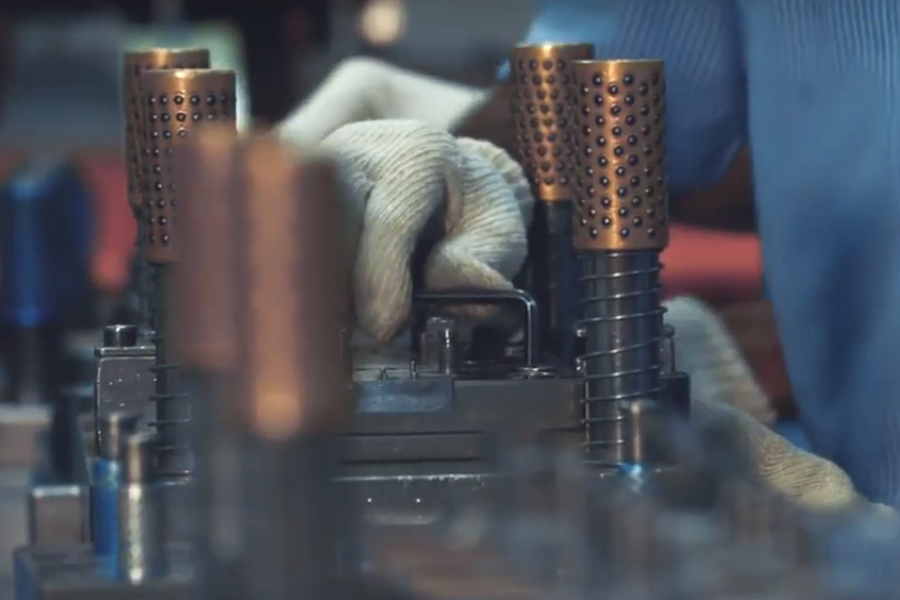

Dies work in several ways and the basic operations that they provide are shearing, drawing, blanking, and bending as well. These have specially designed metal cavity that helps give preferred shape and design to the metal being fed. There are two parts of a die; the upper part is connected to the slide and the lower is connected to the bed. In the die there is punch that helps push metal sheet through the die and this helps achieve actual shaping function. The overall pattern then can be used to attain three-dimensional lettering and shaping on the final product. In this way, the metal stamping dies become an important asset to the industries.

Metal stamping dies as per the need

The industries are taking rapid strides toward development and so there is no one specific need. There are several ways in which the industries can benefit in the long run. There are numerous designs of dies being used for metal stamping. There are progressive dies, transfer dies, and single station dies, and so on. At the end of the day, the precision metal stamping company decides on what die is best for a particular project to take place smoothly. Once the client requests for a project to be handled, the engineering team then starts their work around coming up with the best design for a particular project.

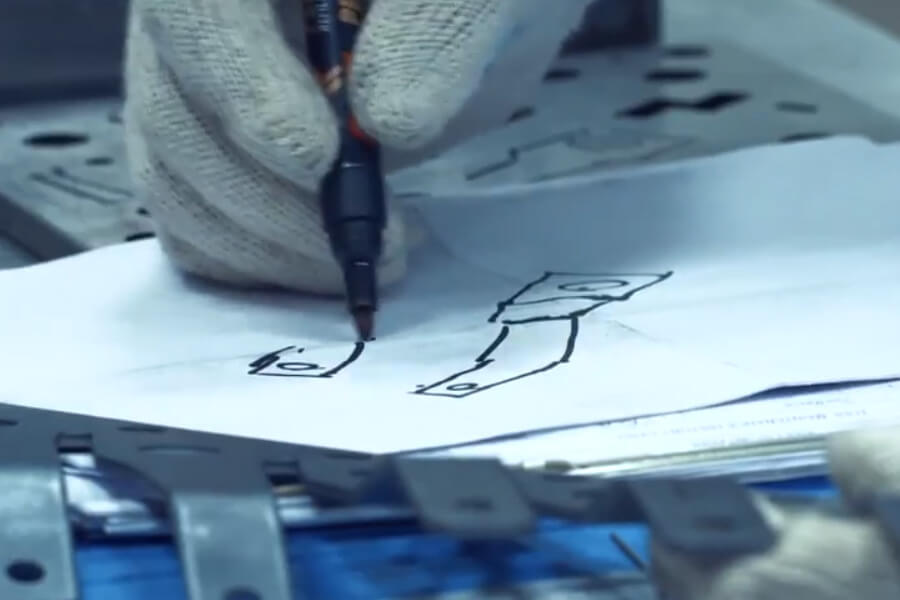

Who is a die maker?

Die maker is an experienced machinist that designs and creates tools required for metal stamping. These professionals are trained professionally and also possess on the job training to be the best in this field. The use of latest technology is evident with experienced professionals and they make sure to always exceed client requirements in this regard. Once the requirement for a die goes to the professional he/she works with the design using latest software and develops the tool. The big companies working in this field have a large team of professionals working in this sector.

What is the cost?

The cost of metal stamping dies is on a higher side. There is a lot of competition in this field as well. However, a wise course is to go with in house tool room with the precision metal stamping company. This ensures that there are no loopholes and that the company provides best result when it comes to stamping. It is best to not go with the cheapest option but to look for something that is more solid.

Dies that are latest

This only means the use of latest technology in construction in the metal stamping dies. The professionals these days work with the latest software and come up with best designs that save money and add more efficiency to the project. This way the client is able to save a lot of money on the overall project. So it is crucial for a company to only hire the metal stamping die maker that uses latest technology and provides efficient solution.

Eigen: Partner in die making

Eigen has experience of over 12 years and has lived up to the name of being the best in industry. Throughout these years there have been numerous challenging feats being accomplished by these professionals. The company ensures that they provide the best of quality. The in-house tool room ensures that client get what they want in less time, expenses and hassles at the same time. There is a clear communication policy in the team from the inception of a project to the final delivery. Eigen team ensure that clients receive their final deliveries within the stipulated time.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.