Punch Press Dies – Set Up and Working In the Manufacturing Industry

- Design and Engineering |

- Jul 23, 2019

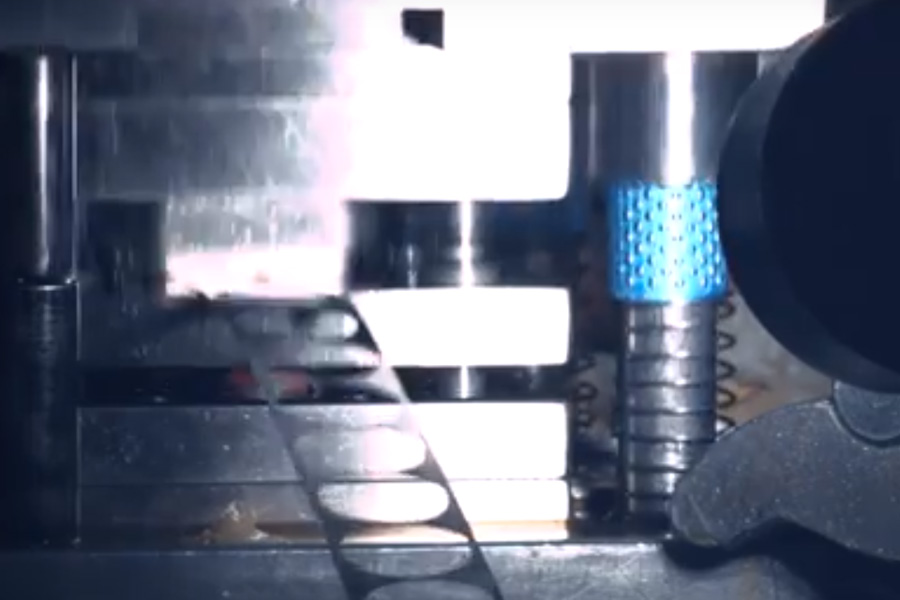

Manufacturing industry is booming and customer demands are skyrocketing. With keeping the higher customer expectations on quality and quantity, setting up the punch press dies playa crucial role. The punch press dies are formed in several shapes and sizes depending upon the component being manufactured. It is crucial to check that the machine is at the proper height and regularly lubricated to prevent it from being overloaded. Taps, drills, other forming tools and dies are used in punch press to deliver the desired results.

Although the capacity varies, the punch presses uses around 25 tons to shape and bend metal sheets. It is crucial to check for dull areas or cracks on the face of those dies before inserting the dies into the magazine. Either sharpen the die at your machine shop or send it out for sharpening, but ensure that this step is never overlooked. Ensure all the dies are almost the same height. Finally, lubricate all the dies in order to keep the punching operations smooth.

- According to the program, set the clamps to hold the material down.

- Before you start to punch the material make sure that no clamps are obstructing the dies.

- A slight mistake at this particular step could be damaging the machine; it could damage the material, worse yet, could damage the die itself.

In order to prevent a similar type of damage, reaffirm the locations of all the clamps during repositioning as well.Make the first run a trial run by stopping the machine occasionally, so that you can inspect the progress of the program and also to check and to ensure if the dies were set up correctly. If you find that changes are necessary, you can make edits right then and there and restart the program from that point on. When the first piece is completed and it gets approved, no more stops will be needed unless a die becomes too dull to continue or perhaps breaks.

Successful working of punch press dies

The punch encounters both tensile and compressive forces as the punching operation progresses. Make sure that the slug is discharged when the punch penetrates the die because if not, because the material may scrape the flanks. Punch and die manufacturers need to always keep in mind that when the punch reaches conclusion of a stroke, it quickly starts to draw back again. So the punching action includes two steps, and these actions add significant amount of force to the tip of the punch.

The careful design, planning, and dimensions added into the tooling helps in minimizing the effects that could otherwise be evident due to lack of planning. Reputed industries use top quality steel that has metallurgical properties when making a tool because these are capable of resisting edge wear, chipping and cracking during several parts of the lifecycle.

Punching a hole competently requires precise alignment between the die and the punch. Good alignment between the die and punch, angular and concentric, makes it possible for the punch to operate without making a contact with the die. Die clearance is another important consideration which has an impact on the overall dimensions of the punch and die. It is important to maintain consistent clearance around the die and this is especially important with rectangular or square shaped tools. Punch press die maintains a uniform clearance when at the corners there is an appropriately planned radius set. Punch press die clearance is further enhanced with the thickness of the material, and this also happens with the radius size. When the right radius is implement it helps to improve both the die strength and part quality.

The function of toolholder system

As the name suggests, the function of toolholder is to hold the workpiece flat while guiding the punch tip to complete a cycle. Reliability, accuracy, and repeatability differentiate various tool holding systems. The toolholding systems are designed to allow an interface between the punch press machine and punch press die. Accurate external and internal features make is possible to provide concentric orientation, alignment, and punch tip’s angular alignment. Additionally, even during the high speeds they make it possible for reliable stripping.

Conclusion:

A guided system with its punch press dies is capable of producing good quality parts and between greater intervals. This is noticed when hard material are punched at high press speeds. When the guided tooling systems are efficiently planned and designed, these help in getting more robust results and the produced components are long-lasting.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.