Your Guide for Metal Stamping Kit

- Precision Metal Stamping |

- Feb 11, 2019

Look around yourself. You will likely see a number of metal objects. In all probability, these metal items have gone through a metal stamping process. Metal stamping is the process where sheet metal or metal coils are formed into specific shapes. The process might include forming, trimming, bending, shaping, cutting, punching and so on. Well designed presses and dies, or the metal stamping kit, along with expert engineering is what ensures a quality product. Precision metal stamping involves producing metal items that have intricate or complex designs. It is highly accurate and allows for a number of processes to be handled in the same operation or as a series of operations.

Advantages of precision metal stamping

One key advantage of precision metal stamping is the production speed. This is a very fast process and because of the high volume of production, the per piece costs cut down drastically. Thus intricate and complex products can be produced in a cost-effective and fast manner. The turn-around time is very less.

The different operations that are required for the production can be automated. A number of processes could be handled in a single operation, or they could be automated to take place in a number of sequential operations. Additional secondary operations could also be included in die or press operations. These might include welding, nut or stud inserting, or assembly.

Heavier parts with thicker materials can be easily handled in precision metal stamping. Intricate and complex designs could be created and manufactured easily. Another key advantage of the precision metal stamping process is its high accuracy and tight tolerance level.

Metal stamping dies

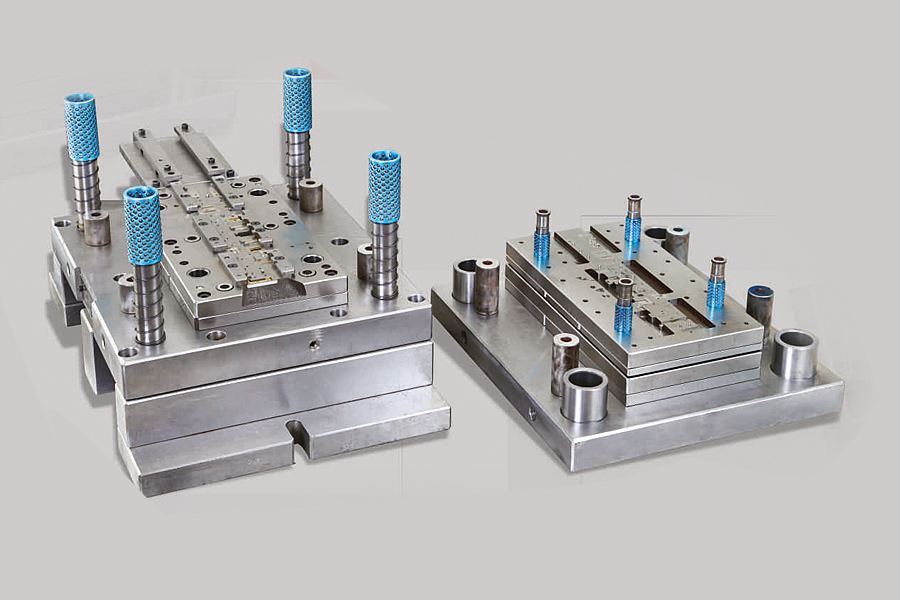

The key to stamping tool is the die. A metal stamping die is a unique precision tool. It performs one or more operations on a metal sheet or coil that eventually results in the finished product. A die is made of tool steel to withstand the high pressures. At times dies are also made of carbide or other strong materials resistant to easy wear and tear. Each die serves a specific purpose. Dies are used in the manufacture of highly complex, minute components used in multiple industries.

A number of highly precise dies are required for precision metal stamping. One type of metal stamping die is the cutting die. Much force is required to cut metal. Generally, two dies with bypassing tool sections are used to cut the sheet or coil. The distance between the two bypassing sections is called the cutting clearance. Cutting clearance would depend on the type of metal, the kind of cut required, and so on. Blanking, piercing, shearing, and lancing are other operations performed by different types of dies.

There are metal stamping tools that are capable of micro precision activities. They can perform several operations, such as bending, cutting, stamping and folding to very minute measurements. The measurements involved could even be 0.002 inches.

Organizations that have cutting edge technology processes will thrive. A simulation and prototype design services software will help potential customers see what they will receive. Anyone having these will have an edge over others.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.