Tool and Die Manufacturing for Industrial Purpose

- Progressive Tooling |

- Jun 5, 2019

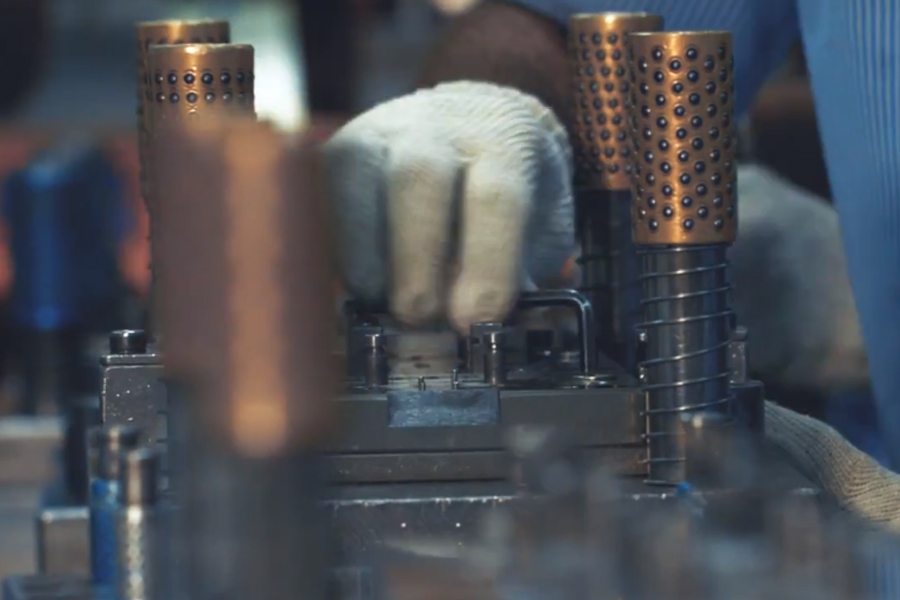

Tool and die manufacturing purpose is a process of placing flat sheet metal in either blank or coil form into a die stamping press where it is formed into different shapes. This results in molded parts which are useful for industrial purpose. The process starts from shaped blanks.

The metal sheet is cut into shaped blanks which are ready for successive forming processes. And then there is a quality check for these blanks on material properties and dimensions. After the quality check, several stamping operations are implemented in order to get the final parts. There will also be another quality verification for the stamped parts both on aesthetic statistic control and dimensional statistic control.

History and usage

Tool and die manufacturing purpose is the industrial art of making plastics molds, stamping dies, and jigs and fixtures which are used in the mass production of solid components.

The fabrication of dies constitutes the major part of the work done in the tool and die manufacturing purpose. Most dies are used in the making of sheet-metal parts that range in various sizes from the panels of an automobile body to the finger stop on a dial telephone. Each die consists of two parts called the punch and die, or male and female. Both segments are mounted firmly in a hydraulically or an electrically driven press. Any metal that is interposed between these sections is shaped or cut to a predetermined form.

Also Read: Tool and Die Manufacturing and Die Casting Company in India

The evolution of modern tool and dies manufacturing purpose can be traced back to Eli Whitney, an American manufacturer and inventor, who first used the idea of planned manufacturing of interchangeable parts. This brought the modern machine shop into existence. Eventually, certain machine shops began to be specialized in the tool and die manufacturing purpose. Towards the second half of the twentieth century, the traditional tool and die process became a necessity for industries.

The tool and die manufacturing purpose does not end with one stamping operation. Rather it is achieved by sequence of multiple operations. Specific parts depend on design and stamping equipment. But, the operations used extensively are blanking, trimming, drawing, piercing, restrike, flanging, hemming and so on. Blanking prepares the initial rough shape of the part in flat sheet. Then, drawing is often the operation to attain depth related form. The following operations, such as flanging, piercing, and hemming, are related to product design operations. Trimming helps in removing the extra material on the periphery of the panel during the draw operation.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

Forming is often not carried out in a single operation because of the complexity of the parts. The geometry of the part determines the production if it has to be carried out in several operational steps through one or several production processes.

The most common types of tool and die manufacturing operations

Cutting Dies:

Cutting dies are used to shear sheet material into a blank. These blanks are exposed to blanking dies which cut the perimeter of the part.

Trimming Die:

Trimming is done on the vertical cutting plane, is implemented by blades attached on the upper base. If trimming has a horizontal component, use of CAM slides set would help.

Piercing Die:

Piercing die is one of the tool and die manufacturing operations that allows to generate the required holes. Fastenings, cable passages, couplings, flanging references are just a few examples.

DISCUSS YOUR PROGRESSIVE TOOLING NEEDS? CONTACT US!

Sheets arrive wrapped in coils, which are cut in pieces according to the component’s size requirements. Some components can be directly manufactured, others require a dedicated tool and die manufacturing purpose. Proper size is calculated from the drawn element, taking in account of flanging sides. So, utilization efficiency is evaluated, calculated and optimized to the highest amount possible. Usually, the relatively simple shapes are cut at high cadency press.

Also Read: Stamping Press Tools Carry High-Speed Production. Know-How?

Essentially, tool and die manufacturing purpose has proved to be an essential part for industries.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.