The Growing Role of Progressive Tools and Components in Manufacturing

- Progressive Tooling |

- Dec 12, 2019

The demand and supply from the manufacturing industry have changed drastically just in the last few years. Keeping up with the requirement, the progressive tool and components play a crucial role. The metal stamping manufacturers progressive tools when there is a need for high volume components production.

Various steps in a project such as piercing, blanking or bending are taken care of in the progressive tooling system. This is the reason why reputed manufacturers only have the best men and technology to work on progressive tools.

The Pressing Need of the Hour

With technology changing at a rapid speed, the consumer requirements are constantly changing and so industries have to come up with new and innovative components. Take the automotive industry for example. In the last decade alone, we have seen a massive increase in the manufacturing and buying of automobiles. What attracts the customers? What is the first thing that they are looking at in the car? As research suggests and our natural inclination, one of the first things that we see is the design. If the manufacturers have to attract the customers enough to make a buying decision, the design needs a change. This is when the progressive tools and components come into the picture.

Why Progressive Tools Are Needed?

When there is a high volume project being handled, time is a constraint and in now way can the quality be compromised. With the progressive tools and components approach, the manufacturers design the dies or tools that will function progressively. As the sheet metal is fed in the press machines, the finished part will have gone through blanking, piercing, and bending when it comes out for further improvement. In the regular press tools and dies, a lot of time is lost when manually moving the components from one press to the other. Progressive tools go hand in hand with the high volume metal stamping projects.

Change Is Constant in Metal Stamping Industry

One of the things that are a norm in metal stamping industry is change. There are always new set of requirements, metal combinations, and custom client requirements. Progressive tools and components weren’t always around for the manufacturers but it evolved with time. It started with an idea and grew to implementation and is now being used across the globe by several reputed manufacturers. So the manufacturing industry is always ready to embrace a new update, change, or modification to the designs with the end goal of providing the best results to the clients.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

The Introduction of Software and Design Tools

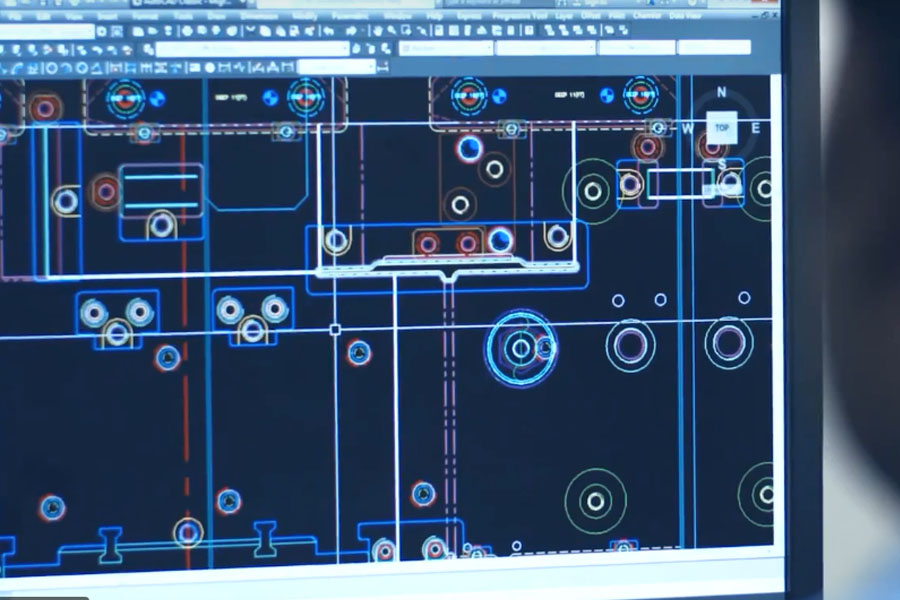

Technology gives a new dimension in every aspect, and the same goes true with progressive tools and components. In order to achieve this, now the tool rooms are equipped with the state of the art software and design tools.

So when designing or manufacturing a tool or die for the required component, the engineering team can work with efficient software specifically developed for the metal stamping industry. The team designs and tests the progressive tools and components before it goes on for live-action. Now rather than spending too much time on designing the overall process has become all the more efficient and fast.

Also Read: Progressive Die vs. Compound Die: Differences and Advantages

The Use of Electronics Sensors

As the complete cycle of progressive tools and components takes place, the addition of electronic sensors has added a new dimension when it comes to efficiency. The electronic sensors are designed to detect any discrepancies in the preset functions. These shut down the press machines if there is a problem detected and the quality team can then easily rectify the problems and move ahead. Rather than relying heavily on just the experienced eyes, the addition of electronic sensors on the press assists these professionals to carry out the stamping smoothly.

Automation in Progressive Tools and Stamping

Automation is yet another awesome addition in the progressive tools and components in manufacturing. During the design to the functioning of progressive tools, there are several repeated tasks that have been automated. In this way, the cognitive skills of the stampers are being used in other areas of stamping. The automation has also reduced several human prone errors that had a huge impact on the time taken in manufacturing. As technology further progresses in the metal stamping industry, we can be sure that many manufacturers will be able to achieve a great level of efficiency.

A Gradual but Steady Growth

Starting from a small workshop to the billion-dollar industry that metal stamping has grown to today, we notice a gradual but steady growth. However, in recent times there have been many new advancements that manufacturing industries need to embrace to keep up with the quality and customer requirements. What advancement in technology will you embrace? Will it be a software, design technique, or methodology? Well, the answer to this is best given by the experienced manufacturers who work closely with the customers every day to keep up with their increasing demands.

DISCUSS YOUR PROGRESSIVE TOOLING NEEDS? CONTACT US!

Benefits to the Customers

One of the benefits to the metal stamping customers with the progressive tools and components in manufacturing is the efficiency, but it is also the reduced cost that benefits them. With the efficient planning and design of progressive tools, the manufacturers are able to reduce the overall scrap material. In a high volume project, even a little difference in the scrap material can make a huge impact on the customers cost.

Also Read: Types of Progressive Tools That You Should Know About

Eigen: Leaders in Progressive Tools and Components in Manufacturing

Eigen has years of experience in the progressive tools and components industry. However, just relying on the 13+ years of experience is not why a global clientele happy. More importantly, it is the strategic implementation of technology in progressive tool design and manufacturing that helps to keep up with the growing customer demands. Eigen currently handles several sophisticated designs and customer requirements in progressive stamping. The ISO certification is just one of the many achievements of Eigen and there are still many more exciting projects lined up. If you have a requirement in progressive tools and components, let the Eigen team know and they will provide you with the most efficient results.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.