Overview of Sheet Metal Press Tool Design in the Manufacturing Industry

- Design and Engineering |

- Jul 3, 2019

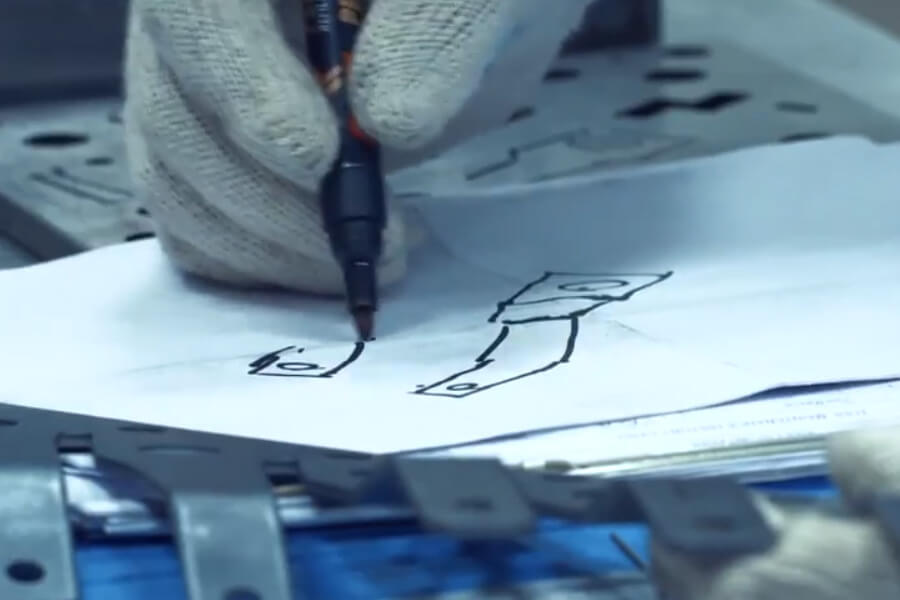

The sheet metal working process is primarily used in various aspects of industrial and commercial production. Countless everyday objects are constructed by means of sheet metal press tool design. Therefore many manufacturers are engaged in developing the trends using their innovative ideas. Especially in sheet metal press tool design, they make various die sets for various functions such as compound die, progressive die, transfer die, modular die, steel-rule die, sectional die and so on. These dies function with their own criteria.

Sheet metal press tool designs are generally related to cutting and forming operations. Generally, the thickness of sheet metal is somewhere between a ¼ inch and 1/64 inch. Stamping tool design could be made to perform several operations such as Bending, Blanking, Shearing, Stamping, Punching, etc. Material selection is a major parameter for such applications. So, complex designs of sheet metals are achieved by using various sheet metal press tool designs and dies.

Sheet metal press tool designs are used for making shaped components, from as small and simple as soda cans to as complicated and huge as automotive car bodies. In simple terms, sheet metal is metal formed into thin and flat pieces. In metalworking sheet metal is one of the fundamental forms used and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed from it.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

Stamping tool designs:

The key factor for the high volume production on a continuous basis for all the sheet metal components is Progressive Tool Design.

A wide range of Progressive Tools for complex parts with dimensionally & functionally critical components can be produced by progressive tool design.

Also Read: Progressive Die vs. Compound Die: Differences and Advantages

Factors to consider in progressive tools design:-

- Economic Strip Layout needs to be approved by the customer for the utmost utilization of the strip and to confirm the burr directions.

- For easy replacement in case of breakage, each stage of the progressive tool is provided with Tool proofed die insert.

- Also, for the easy re-sharpening, the non-cutting or cutting die inserts will have a replaceable spacer.

- In stamping tool design, along with Die set which is guided with 4-6 Main Guides, the Stripper, Punch holder and die plates will have Micro Guides for accurate alignment.

- For the trouble-free Autorun Strip, Guide or Lifter are provided.

- To ensure proper strip feeding into the die, progressive tool design should incorporate Strip Guide extensions.

- To absorb the thrust load on the punch and die inserts, back plates for punch and die need to be provided.

- In-case the strip happens to be misfed into the machine, misfeed pilot arrangement is to be provided to stop the press.

- Stripper bottoming buttons are to be provided in progressive tool design to transfer the forming Load on the Top Half for forming operations.

- Stamping tool design should have die rest buttons to balance the stripper and to ensure that the stripper is not clamping the strip but is just contacting the strip.

- All die and punch reliefs need to be provided to avoid damage marks on the formed areas.

- Proper Slug reliefs are to be ensured for the free fall of the slug and components.

- Side actuated or top actuated cam –punch and dies are used for the forming and bending stages to accommodate the strip thickness variation and also to adjust the form consistency for all the critical components.

- All the required safety sensors should be provided in the stamping tool design based on the customer’s requirement.

Also Read: Advanced Cutting Tool design and Fabrication Mechanism

DISCUSS YOUR PROGRESSIVE TOOLING NEEDS? CONTACT US!

Conclusion:

Sheet metal press tool design lies right at the heart of industrial manufacturing. In almost all products that have multiple parts, at least one of these parts will be formed by a press tool using stamping tool design. The major reason for this popularity is that the sheet metal itself is cheap and forming and joining operations can be performed efficiently and quickly. Annual production volumes can run into the hundreds of thousands. Additionally, sheet metal can be textured or painted to have many different kinds of feel and look, and it can provide a distinct product character, as seen in classic car bodies. In short, it is an absolute must that any sheet metal press tool designer should know about this manufacturing principle.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.