Different Types of Die Used in Manufacturing

- Progressive Tooling |

- Aug 3, 2022

A die is considered the most vital part of the engineering and manufacturing process. It is important to understand its various kinds and how they can benefit your operations in the metal stamping industry. It is vital to remember the various types of dies. It is on you to decide the one that best suits your needs.

What is the use of dies in Manufacturing?

Dies is the machine tool used across several manufacturing industries for cutting the metal into its desired shape or cutting threads on the external surface of the pipe, round rods, etc. It helps in getting threads of the right size and specifications, facilitating at the start of the thread using a progressive die.

The primary aim of using the die stock is that it is hand operated. These are high carbon steel, alloy steel, and high-speed steel, with square and circular shapes.

The dies are specifically classified based on their use, like the stamping dies used in press works, drawing dies used in the manufacture of wires, and casting dies used in the moulding processes.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

Types of Dices

Here are the top 7 types of dies used in the tool and die manufacturing industry!

#1. Simple Die

A single operation die (or a simple die) is designed specifically to perform only a single operation across every stroke of the press sliding. The simple die is further classified based on its cutting and forming functions.

The cutting dies are used in operations that include blanking, notching, trimming, and more. The forming die is used in curling and bending etc.

#2. Compound Die

The compound die design performs several operations like punching or cutting with a single stroke. For instance, it can perform the cutting and forming operations in a single stroke and is the most effective way for high-volume parts.

The compound or progressive dies are used for stamping simple flat parts such as the washer. It consists of springs and punches on both its ends. The upper region of the punch is connected with the ram, comes into contact with the metal, and pierces the hole.

As the punch moves downward, the spring compresses after a certain range lowering the punch, moving it upwards, and cutting the holes.

Also Read- Understanding Press Tool and Die Process

#3. Combination Die

The combination die is similar to the compound die in terms of efficiency and design. It can tackle more than a single operation at once, allowing it to deliver faster and more significant results. Additionally, the combination die is well suited for shaping and cutting applications.

You need to understand the types of dies used in the tool and die industries if you need to finish the blanking or the punching operations combined with the bending operation. It is a versatile tool playing a distinctive role across many metal work applications ranging from mining equipment manufacturing to electronics along with the development of the application.

#4. Transfer Die

The transfer die uses a single press for operating multiple tools. It is used in higher volumes for production work where the transfer dies come with several benefits. It can transfer freely, working with the addition of more shapes to the part till the metal workpiece achieves its final shape.

In earlier times, the processes were done using individual presses, and the workpiece was hand transferred from press to press, even die to die. The use of automation has streamlined the process.

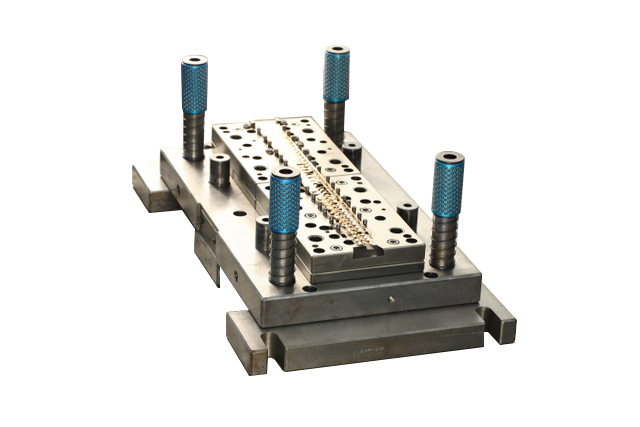

#5. Progressive Die

The progressive die is used widely in the production processes for various industrial parts, including the electronic and automotive sectors. It is the kind of die stamping press that consists of various individual workstations, each of which performs one or more different operations on the part. The part of the work is transferred from station to station by stock drop that cuts out the strip in the final operation.

DISCUSS YOUR PROGRESSIVE TOOLING NEEDS? CONTACT US!

#6. Acron Die

It is a modern die. It is used for cutting the external threads on the pipe’s fittings in a hole or a groove.

The die is also similar to a nut in which the threads are cut within and are cut intermittently. It is tapered from one end for convenience and is moved by holding it in a special holder.

#7. Pipe Die

It is the die that is almost similar to the progressive die that is used for cutting threads on the gas, water pipes, and oil pipes. It is the die of two to four elements fitting across different die handles.

Also Read- Get to Know 5 Types of Dies used in Sheet Metal Die Stamping

There is an adjusting screw on the handles or the stocks to adjust the die. There is a guide fitted in stock or even the handle guiding the die to move straight. The thread cuts with the die are of a specific kind since this die cuts the threads in the tape.

We have thus read about the seven most popular types of die and how vital it is for the engineering and manufacturing industry.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.