Benefits of Using Combination Die For Your Metal Stamping Project

- Precision Metal Stamping |

- Jan 22, 2020

Year 2019 has been a happening one, and this is very true in the metal stamping industry. The need for metal stamping has drastically increased around the globe. In order to keep up with the growing customer demands, the metal stamping industries are implementing new methodologies and techniques to deliver quantity and quality metal stamping components. Combination die work is an effective part of the strategy when it comes to driving home the best results.

There are several benefits of using combination die, let’s take a look at some of the major benefits.

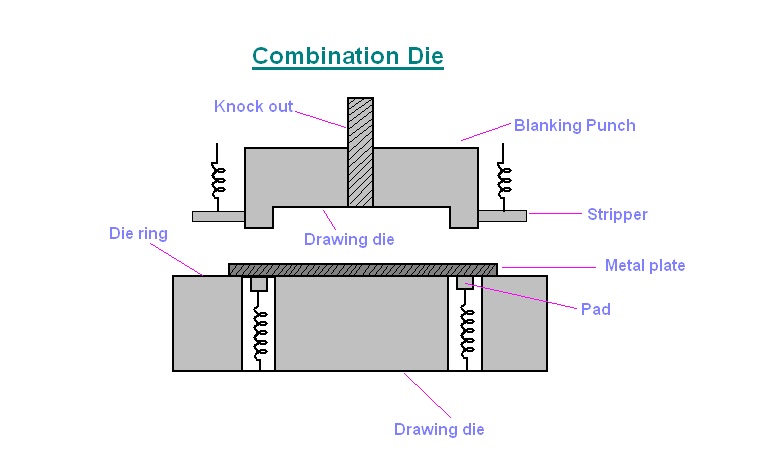

What Exactly is Combination Die?

With the growing demands in the metal stamping industry, the work stations are required to produce more in less time to keep in sync. Combination dies are used in work stations to handle a combination of processes.

In these dies, the cutting of the metal sheet is combined with other actions such as drawing or bending. So as the name suggests, combination dies are designed to handle a combination of tasks or processes on the work stations. These are widely used across the globe, and here are some of the benefits that manufacturers are experiencing.

Demand and Supply

Industries such as automobile, aerospace, electrical and electrical are progressing with every passing day. Along with the progress, there is also a competition within the industries with the other companies. In order to keep up with the competition or rather have a competitive edge over the others, it is crucial that businesses have a regular supply of new and innovative products. This is when it helps to have combination dies as it helps to keep up with the supply needs and especially when there is a combination task that needs to be performed on the metal sheets.

Cost Savings is a Plus

Typically, the workstations were designed to handle only one task at a time. However, it changed with time when metal stamping manufacturers want to provide cost-efficient services to their customers. With the combination die, it is possible to save a lot of costs because a combination of tasks is handled on one workstation. This reduces the need to design, install and maintain the new dies on workstations and this has a huge impact on the overall project and especially the cost involved. When the customers are able to get their required products at a low cost it is a win-win situation.

EXPLORE OUR PRECISION METAL STAMPING SERVICES

Achieve Quality with Quantity

Metal stamping manufacturers that deliver quantity with quality to their customers are few and combination die makes this easy for the manufacturers. Rather than handling processes such as cutting, blanking, drawing, etc.separately, a combination of them can be handled on one workstation. This comes in handy when working on huge projects. Manufacturers are able to achieve quality by good planning and installing combination dies rather than using several dies for different purposes. In the past, achieving quantity meant that there will be a compromise in the quality but that’s not the case with the latest machines and technology.

Also Read- The Important Function of Metal Stamping Dies

Faster Die Setup Time

Setup time to die is one of the major time-consuming process. However, with the combination die this process is much better. The die setup time is much faster when compared to traditional approaches. When several processes or steps are reduced down to just one with the combination die, it helps to speed up the die setup time and in the complete lifecycle it works out to be effective in saving time, cost, and effort.

Reduced Waste of Metal

Waste or scrap metal is common in metal stamping industry and customers are often used to this waste. However, with the combination dies it is possible to reduce the waste of metal. This helps the customers to save a lot on the overall project expenses. The cost of scrap metal is huge and oftentimes, this cost creates a huge dent if not kept under control. With the combination die it is possible to design it in a way that the die uses maximum sheet metal as possible in the cycle. The customers are able to save money in the scrap waste and this helps them in reducing the cost involved.

High Volumes are Achieved

The manufacturers utilize compound die and combination die in their production processes. This in turn helps in achieving high volume runs without the degradation of tools. High-quality products are achieved by using hard tooling. As the degradation of die doesn’t happen faster, the manufacturers are able to achieve high volumes in their production. Technology and creative minds when at work, it helps manufacturers to plan the project well and save the customers from spending a huge amount of money when the best could be delivered at a lower cost.

Also Read- Choose the Best Raw Materials for Metal Stamping Assembly

Wide Range of Products

Combination dies are effective for manufacturers to create a wide range of components for various products. For example, in the industrial engineering product there may be a need of components with a combination of stamping for efficient functioning. The combination dies can be designed exactly as per the requirement and the project could be easily executed. There is a wide range of possibilities that the manufacturers and customers can explore with the combination. When the latest technology is put to work with the combination die the outcome is in the best interest of the customers and manufacturers.

DISCUSS YOUR PRECISION METAL STAMPING NEEDS? CONTACT US!

Eigen: Your Partner in Combination Die

Eigen has an excellent team of metal stamping professionals working with them for many years. The creative minds and experience combined at Eigen can help you execute almost any project under the metal stamping domain. The in-house tool room and fully equipped workstations help to produce a wide range of products every day. At Eigen, the goal is to always scale up and break the barriers that limit creativity in the metal stamping industry. Implementation of the latest technology helps to deliver great quality and quantity metal stamping products to our customers from across the globe. The strategic location near the Banglore International Airport is another helpful factor that helps Eigen deliver to the global clientele on time and with the highest standard protocol.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.