Key Factors to Consider when Making Metal Parts with Progressive Die Stamping

- Metal Stamping |

- Oct 3, 2022

The progressive die stamping technique is common in stamping manufacturing various parts in different sectors. So, engineering and purchasing managers must get standard parts and components. While doing this, they need to consider the price depending on the function and application of the parts. In addition, you also need to pick a manufacturer with the ability and experience to make the parts. So, what is progressive die stamping, and factors do you need to consider during the process?

What is Progressive Die Stamping?

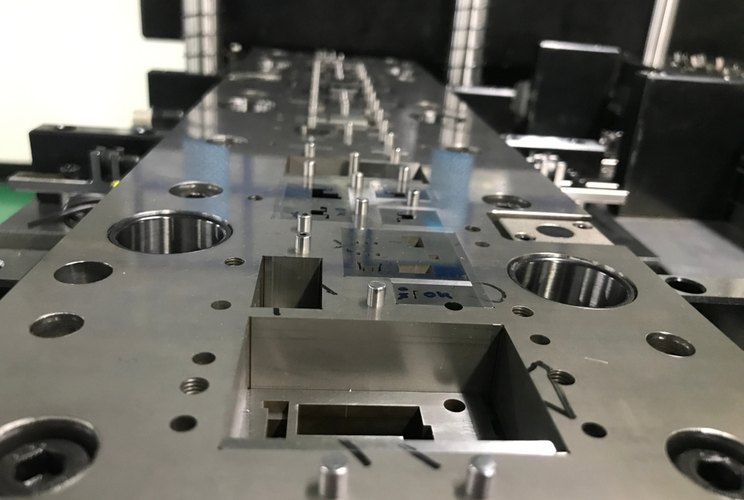

It’s a metal forming technique that can create complex parts in various stages for different sectors and applications. This technique includes several stages, and each has a different operation on the part or component. During the process, the metal coils are fed through various stations of an auto transfer production line, and each time a new feature is completed. Then a high tonnage press machine uses extreme pressure to dictate the shape of the part. Finally, the shapes can be created through punching, bending, forming, drawing, and coining.

The creation of parts using progressive die stamping parts is affected by several key requirements. They include the complexity, size, and number of parts required. Therefore, this technique is best for producing large volumes of parts while keeping costs low. In addition, the technique offers several benefits, which include:

- Lower labor costs

- Less scrap

- Less setup time

- Fast creation of parts with close tolerances

- Saves time and money due to a combination of several operations.

- The method has several benefits, as listed, but it’s important to know the factors to consider while using it.

Also Read- Progressive Die vs. Compound Die: Differences and Advantages

Factors to consider when making metal parts using a progressive stamping die technique

While using this method to produce parts, there are factors to consider, and they include:

Production Volume

The creation of metal parts using progressive die stamping is designed for high-volume production. If you are looking forward to making a lot of parts, this is the right process for you. However, to make the process swift, you need a stamping parts supplier to ensure constant flow. It will ensure that your work runs swiftly and efficiently throughout the year.

Cost

In producing parts for business, it’s crucial to consider the cost. In any business, everyone is looking at how they will make profits in the long run. So, it’s crucial to check the tooling setup costs and per-piece cost while making metal parts. There are several methods you can make metal parts, and you need to pick one that suits your budget and will offer quality products.

For instance, the progressive die and transfer press tooling have higher setup costs but lower per piece costs. On the other hand, stage tooling has lower setup costs but higher costs per piece. Therefore, the progressive die is appropriate as you can produce volumes of parts while saving money and time.

Lead time

In any project, it’s important to consider what you need. One of the things to consider is the project deadlines to decide which is the best method. For example, the stage tooling method has a low production speed, so it’s appropriate for a longer project. However, if the project is urgent, the best method is the progressive die, which has a fast production speed. Therefore, before the start of any project, know the timeline you have for its completion.

The Thickness and Size of the Parts

To produce complex parts, punching, forming, and drawing are involved in their creation of various sizes and thicknesses. If you are producing complex and large volumes of parts, the best method is progressive stamping. But before getting a stamping parts supplier, you need to know their machinability capabilities. You need to know if they can stamp larger parts with different degrees of thicknesses. Then, when you create the parts using the method, you will get quality parts faster.

Also Read- Types of Progressive Tools That You Should Know About

Tooling Method

Tooling and the volume of the parts you need is other important factor to consider. Remember, you need to be sure the manufacturer making them has the capabilities to create the parts and deliver them on time. If the manufacturer cannot provide the quality and quantity, it will affect the product line and overall output. So be cautious when picking the manufacturers and ensure they have the right tools for the job.

Materials used

The material used in making the parts depends on the function, resistance, and strength required in its application. For example, they need high resistance strength if the parts are used in the aerospace, automotive, or mining sectors. It’s because they operate in extreme conditions and need to be stronger and faster to wear and tear. Therefore, metals such as aluminum and their alloys are good because they are strong and corrosion-resistant. So, when parts and components are made from metal using progressive stamping dies, you are assured of durability and quality.

Progressive die stamping is among the best techniques to make parts for various industries. Parts made through this method are strong and resistant, making them suitable to work in extreme conditions. But before creating parts, ensure you consider the size, shape, order volume, materials to use, and the tooling method. All these will help you create quality, durable and reliable parts.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.