Combination Die For Metal Stamping

- Precision Metal Stamping |

- Jan 22, 2020

The ongoing development and progress being made in the metal stamping sector have been driven by the growing need for precision components to be produced more quickly and at lower prices than ever before. With increased competition amongst metal stamping manufacturers, there will be an expectation to utilize advanced tooling options that offer capabilities to produce both high quality and high volumes while maintaining the same operational efficiencies previously experienced.

Metal stamping companies can utilize combination dies as a very effective way to produce high-quality products quickly and consistently. Using combination dies allows companies to eliminate unnecessary handling of products during the production process by combining numerous operations into one single press stroke. Combination dies will allow metal stamping companies to save money by reducing their cycle time and, ultimately, produce excellent quality products at high volume levels to meet the needs of industrial engineering projects.

What is a Combination Die?

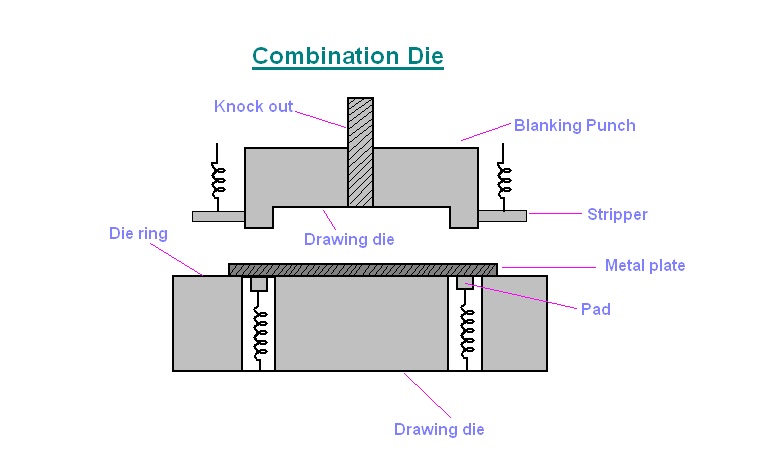

A combination die is a type of die that can perform both cutting operations and forming operations in only one stroke through the use of a press. Simple form dies can perform 1 operation (cutting) per-stroke, but combination dies can be engineered to perform multiple operations simultaneously (blanking, piercing, bending and forming). Combination dies are therefore able to produce more complex parts faster than simple dies.

With the growing demands in the metal stamping industry, the work stations are required to produce more in less time to keep in sync. Combination dies are used in work stations to handle a combination of processes.

In these dies, the cutting of the metal sheet is combined with other actions such as drawing or bending. So as the name suggests, combination dies are designed to handle a combination of tasks or processes on the work stations. These are widely used across the globe, and here are some of the benefits that manufacturers are experiencing.

How a Combination Die Works?

A combination die works by integrating multiple functional operations into one die tool set so that several tasks are completed in a single press cycle. The die is mounted in a stamping press, and as the press ram descends, the die performs coordinated cutting and forming actions to shape the metal workpiece.

Single Stroke Execution: All cutting and forming operations occur during a single downward stroke of the press, which means the metal moves closer to its finished shape each time the press closes.

Multiple Operations at One Stage: Unlike progressive dies that move the material through different stations, combination dies perform multiple cutting and forming tasks at the same station and in the same stroke.

Integrated Functional Sections: The die assembly contains dedicated tooling for each required process, such as blanking edges, piercing holes, and bending or forming features, arranged so they operate in sync as the press descends.

Simultaneous Cutting and Forming: Because both cutting (e.g., blanking outer profiles and piercing internal contours) and forming (e.g., bending or shaping) occur together, the workpiece requires fewer secondary operations and less handling.

EXPLORE OUR PRECISION METAL STAMPING SERVICES

Key Functions of a Combination Die

Cutting and Forming Operations

The combination die is used to cut and form parts through material removal and/or forming in a single operation.

- Blanking – cutting the outer shape of the component

- Piercing – creating internal holes or cut-outs

- Bending / Forming – shaping edges or contours

The advantages of using a combination die include superior dimensional accuracy for producing complicated components.

Multi-Operation Capability

Combination dies accomplish multiple operations concurrently, thereby facilitating the quick creation of intricate metal components. In addition, as a result of this single-step approach to creating a complicated component, there is a decreased amount of variability between processes and improved consistency in large production runs.

Also Read- The Important Function of Metal Stamping Dies

Benefits of Using Combination Die For Metal Stamping

Cost Reduction: By combining several operations into one die, there is no need to install, maintain and operate separate dies, which typically reduces the overall manufacturing cost.

Quality and Quantity: By combining cutting and forming into a single process, the throughput of parts is increased, enabling a greater volume of parts to be produced without compromising quality.

Shorter Setup Time: Since there are fewer sets of operations to set up, the overall setup time for all operations is shorter.

Less Material Waste: The design of combination dies optimises the material used to produce stamped components, reducing scrap and overall material costs.

Increased Volume Production: Combination dies allow for the production of large quantities of metal stamping components with a high degree of accuracy and tool life.

Also Read- Choose the Best Raw Materials for Metal Stamping Assembly

Applications of Combination Dies

Combining dies are utilized in high volume production for medium and small metal stamping where accuracy and precision are paramount, and apply to:

- automotive components

- aerospace parts

- electronics and electrical enclosures

- industrial hardware and brackets

The industries listed above benefit from the speed, precision and repeatability provided by combining dies.

DISCUSS YOUR PRECISION METAL STAMPING NEEDS? CONTACT US!

Combination Die vs Compound Die

Though it may be hard to tell the difference between them, Combination Dies and Compound Dies have different functions:

- A compound die performs multiple cutting operations only (such as piercing and blanking) in a single stroke.

- A combination die performs cutting operations along with forming or bending operations in the same stroke.

This is why Combination Dies are more efficient when producing products that require some sort of shaping or forming and require multiple cutting processes for the same cycle.

When To Use Combination Dies?

A combination die is ideal when:

- Parts require both cutting and forming

- Production volumes are high

- Secondary operations need to be eliminated

- Consistency and cycle-time reduction are priorities

However, combination dies may not be the best choice when parts are extremely complicated with numerous forming stages; in these situations, progressive dies could provide a better alternative.

Eigen: Your Partner in Combination Die

Eigen has an excellent team of metal stamping professionals working with them for many years. The creative minds and experience combined at Eigen can help you execute almost any project under the metal stamping domain. The in-house tool room and fully equipped workstations help to produce a wide range of products every day. At Eigen, the goal is to always scale up and break the barriers that limit creativity in the metal stamping industry. Implementation of the latest technology helps to deliver great quality and quantity metal stamping products to our customers from across the globe. The strategic location near the Banglore International Airport is another helpful factor that helps Eigen deliver to the global clientele on time and with the highest standard protocol.

Frequently Asked Questions

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.