What You Need to Know About Progressive Die Stamping

- Progressive Tooling |

- Oct 9, 2019

Fabricating complex parts in earlier days was an inefficient and costly affair. Either a manufacturer could repeatedly change the tool in a single press or use multiple presses each performing single action to produce one part. This resulted in long load times and a high labor cost.

With progressive die stamping, a manufacturer can eliminate all these hassles and produce better quality parts faster and in a cost-effective manner.

What is Progressive Die Stamping?

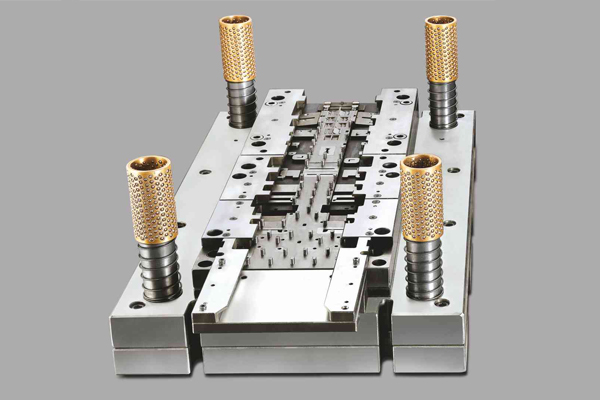

Progressive Die Stamping is a metal stamping process used to cut and form raw sheets of metal using a stamping die. It comprises several individual workstations which perform one or more operations on that part. The progressive die can perform various actions like cutting, coining, punching, bending, lancing, shaving, extruding, drawing and embossing, etc.

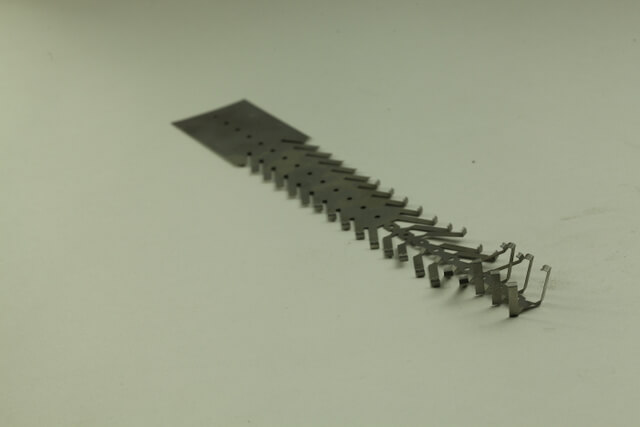

As the name suggests, progressive die stamping encompasses many progressive steps where the raw material is pressed simultaneously and sequentially in an automatic feeding system. Each step is built on the previous step until the desired shape is achieved. All these steps have the same basic setup with some possible variations.

Progressive Die Stamping vs Transfer Die Stamping

Progressive die stamping is similar to transfer die stamping with some differences in the working nature. In case of transfer die stamping, the part is transferred from one station to another by a mechanical transport system. It is typically used for producing large parts like tube applications, frames, shells, and structural components. Whereas, progressive die metal stamping is ideal for larger volume production of smaller parts.

EXPLORE OUR PROGRESSIVE TOOLING SERVICES

Working Process

At first, the die is fitted into the stamping press by a trained employee. Once the proper adjustment is done, the technician triggers the machine. As the press moves up, the top die moves along and allows the material to feed. The die closes as the press moves down, it presses the strip and starts performing the stamping process. This process is repeated numerous times depending upon the part being manufactured.

As the strip moves through the press it is incrementally stamped up to the desired end part shape. Every single stroke of the stamping press removes one completed part from the die.

Also Read- Types of Progressive Tools That You Should Know About

Key Advantages of Progressive Die Stamping

Increased Speed:

Progressive die design process utilizes continuous feed of material through different die stations. When compared with traditional machining, this allows you to create more parts in a shorter time period. For high volume parts, you get the lowest cycle time per part with this stamping process.

Reduction of Scrap:

Progressive die metal stamping involves various forming processes like punching, coining, bending, etc. for producing the end part. As a vast amount of material is used, the volume of scrap produced is very less. This makes it the most cost-effective material for part manufacturers.

Complex Geometrics:

The building nature of the die stations in a progressive stamping tool allows you to create more complex geometrics. Also, all the required geometrics of a part can be achieved in a single operation of the progressive die.

Faster Setup:

Progressive stamping process takes much less time compared to the conventional stamping methods. To produce complex parts, multiple setups, tool changes and die changes are required in traditional stamping, whereas the same can be achieved in one single progressive die operation.

Lower Part Cost:

DISCUSS YOUR PROGRESSIVE TOOLING NEEDS? CONTACT US!

All the above factors contribute to reducing the cost per part manufactured in progressive die stamping.

Applications of Progressive Die Stamping

As multiple cutting and forming operations can be performed simultaneously, progressive die metal stamping is the right choice for a variety of industries for producing multiple small parts quickly.

With the right tools, it also allows you to maintain close tolerances. A range of industries where it can be used are:

- Automotive

- Electronics

- Aerospace

- Food and Beverage

- Agriculture

- Home Care

- Locomotive

- Retail

- Medical

Also Read- Progressive Stamping Die Design Tips

Choose Eigen: Your Partner in Progressive Die Stamping

With more than 10 years of experience in the industry, Eigen is your ideal partner for progressive die stamping for your part production. Our creative team of engineers takes care of every detail to make sure you get the highest quality parts in the least possible time.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.